Подключение и настройка SKR 1.4 +TMC2209 +датчик филамента

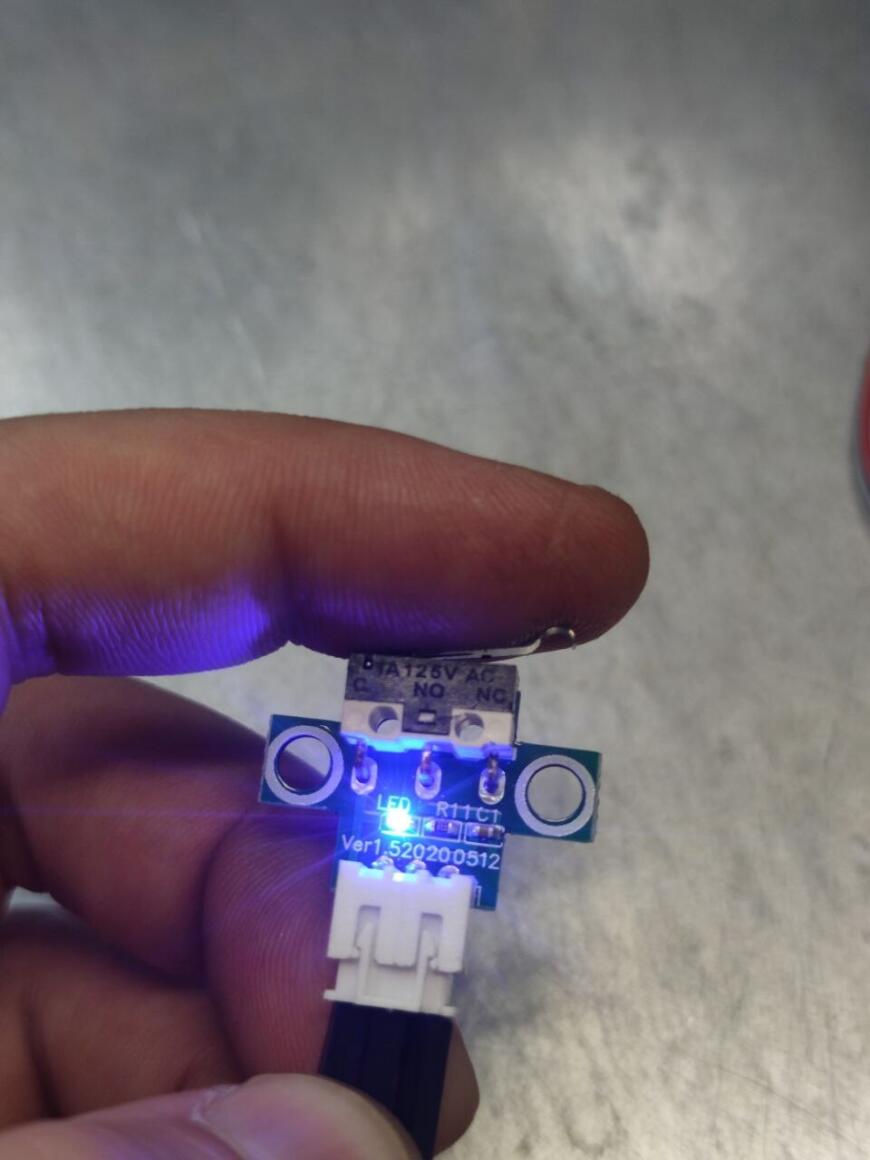

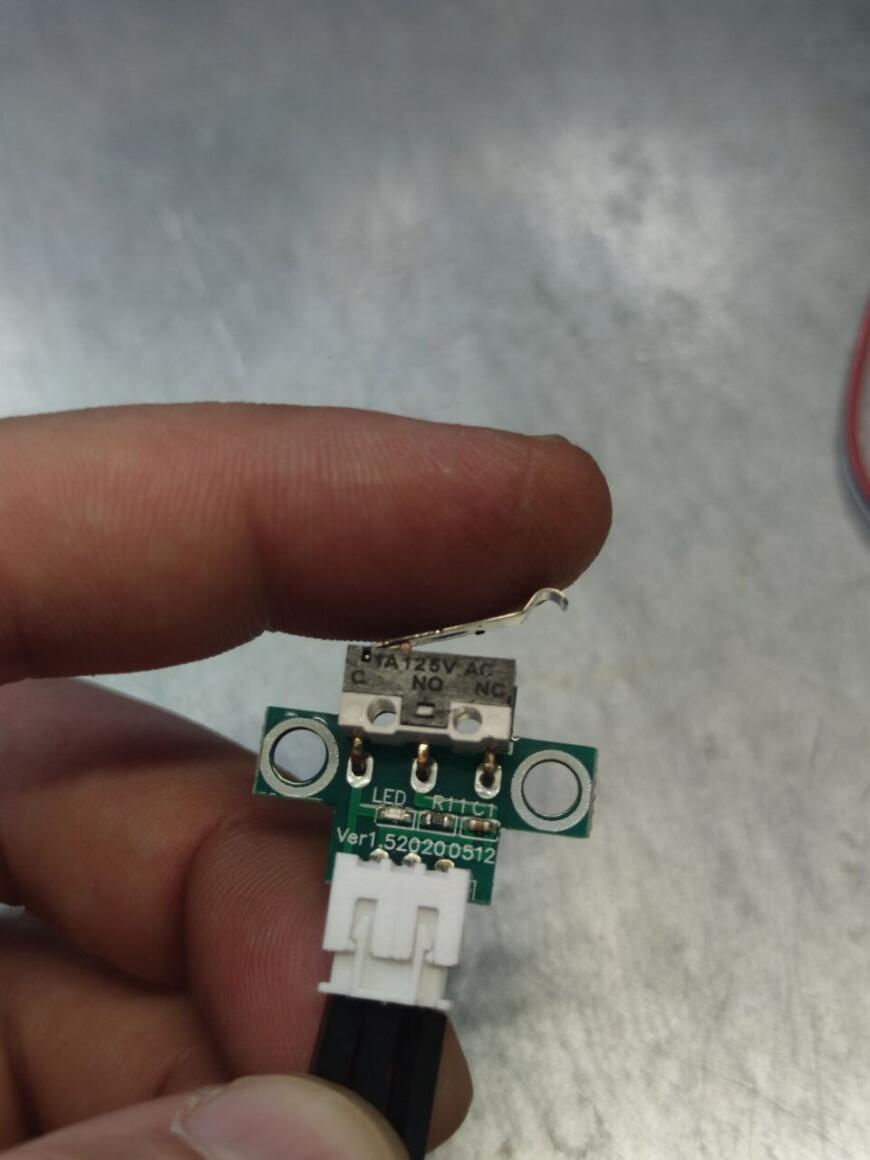

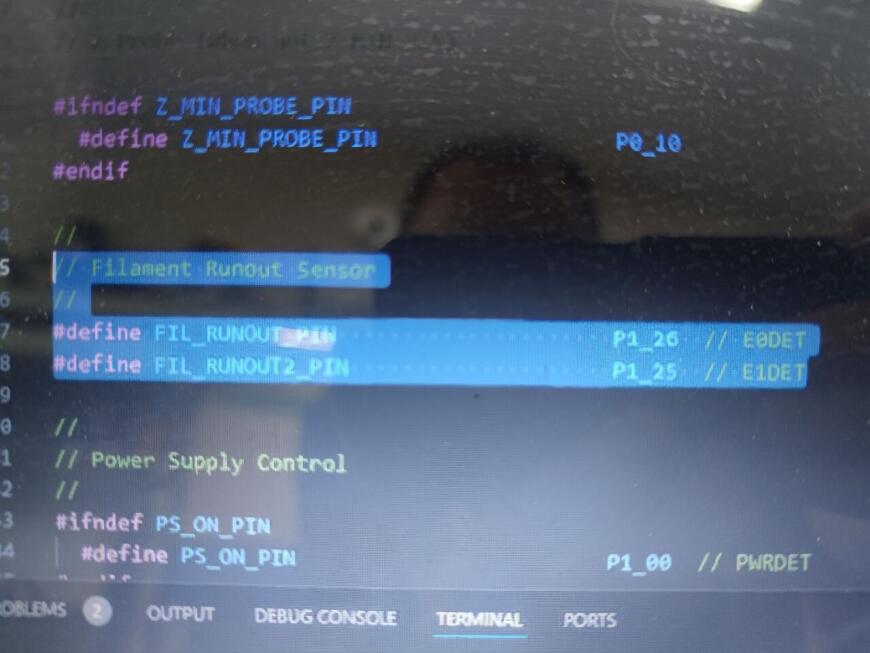

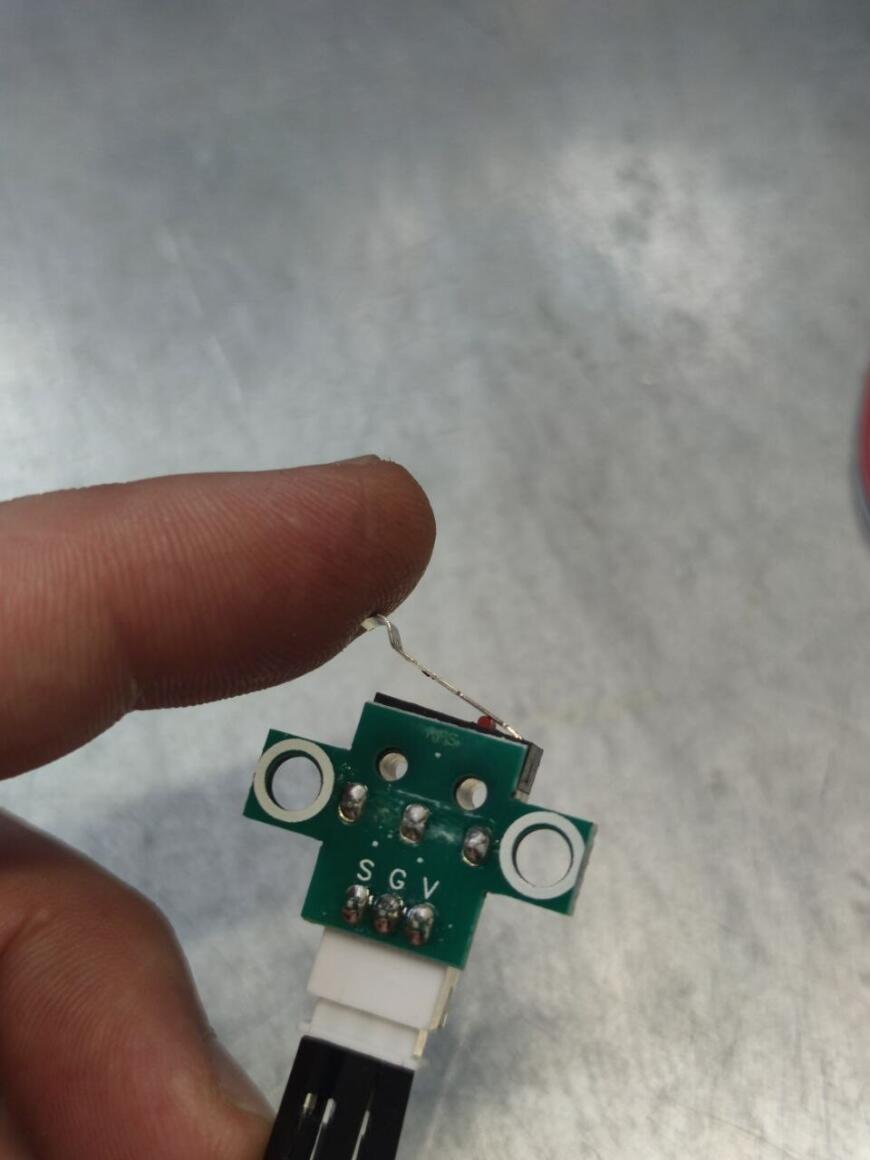

Всех приветствую Подключаю датчик окончания филамента в SKR 1.4 +TMC2209, принтер ender 3. Делал все по инструкции схожей темы на форуме: https://www.youtube.com/watch?v=TrDJmYcZ0Ic&t=74s, все что на этом видео повторил за исключением выбора дисплея- у меня дисплей CR-10- обычный от ender 3. Прошивка компилируется. Запускаю печать, делаю имитацию обрыва нити, принтер останавливается на паузу, просит заменить пруток. После замены прутка, снова уходит в паузу- не срабатывает концевик. Концевик филамента проверил в программе репитер хост, все работает: в разомкнутом состоянии "filament: open" , вставляю пруток, светодиод загорается о срабатывании "filament: triggered". Подключение концевика правильное- проверял с обратной стороны на плате BTT SKR 1.4. Дополнительно в прошивке посмотрел какой пин задействован на эту функцию- pin_26 // E0DET. Помогите разобраться почему не срабатывает датчик? Модель датчика на фото.

#ifndef MOTHERBOARD

#define MOTHERBOARD BOARD_BTT_SKR_V1_4

#endif

/

* Select the serial port on the board to use for communication with the host.

* This allows the connection of wireless adapters (for instance) to non-default port pins.

* Serial port -1 is the USB emulated serial port, if available.

* Note: The first serial port (-1 or 0) will always be used by the Arduino bootloader.

*

* :[-1, 0, 1, 2, 3, 4, 5, 6, 7]

*/

#define SERIAL_PORT -1

/

* Serial Port Baud Rate

* This is the default communication speed for all serial ports.

* Set the baud rate defaults for additional serial ports below.

*

* 250000 works in most cases, but you might try a lower speed if

* you commonly experience drop-outs during host printing.

* You may try up to 1000000 to speed up SD file transfer.

*

* :[2400, 9600, 19200, 38400, 57600, 115200, 250000, 500000, 1000000]

*/

#define BAUDRATE 115200

//===========================================================================

//============================= Mechanical Settings =========================

//===========================================================================

// @section machine

// Enable one of the options below for CoreXY, CoreXZ, or CoreYZ kinematics,

// either in the usual order or reversed

//#define COREXY

//#define COREXZ

//#define COREYZ

//#define COREYX

//#define COREZX

//#define COREZY

//#define MARKFORGED_XY // MarkForged. See https://reprap.org/forum/read.php?152,504042

//#define MARKFORGED_YX

// Enable for a belt style printer with endless "Z" motion

//#define BELTPRINTER

// Enable for Polargraph Kinematics

//#define POLARGRAPH

#if ENABLED(POLARGRAPH)

#define POLARGRAPH_MAX_BELT_LEN 1035.0

#define POLAR_SEGMENTS_PER_SECOND 5

#endif

//===========================================================================

//============================== Endstop Settings ===========================

//===========================================================================

// @section endstops

// Specify here all the endstop connectors that are connected to any endstop or probe.

// Almost all printers will be using one per axis. Probes will use one or more of the

// extra connectors. Leave undefined any used for non-endstop and non-probe purposes.

#define USE_XMIN_PLUG

#define USE_YMIN_PLUG

#define USE_ZMIN_PLUG

//#define USE_IMIN_PLUG

//#define USE_JMIN_PLUG

//#define USE_KMIN_PLUG

//#define USE_UMIN_PLUG

//#define USE_VMIN_PLUG

//#define USE_WMIN_PLUG

//#define USE_XMAX_PLUG

//#define USE_YMAX_PLUG

//#define USE_ZMAX_PLUG

//#define USE_IMAX_PLUG

//#define USE_JMAX_PLUG

//#define USE_KMAX_PLUG

//#define USE_UMAX_PLUG

//#define USE_VMAX_PLUG

//#d

Артем, [16.09.2024 16:37]

efine USE_WMAX_PLUG

// Enable pullup for all endstops to prevent a floating state

#define ENDSTOPPULLUPS

#if DISABLED(ENDSTOPPULLUPS)

// Disable ENDSTOPPULLUPS to set pullups individually

//#define ENDSTOPPULLUP_XMIN

//#define ENDSTOPPULLUP_YMIN

//#define ENDSTOPPULLUP_ZMIN

//#define ENDSTOPPULLUP_IMIN

//#define ENDSTOPPULLUP_JMIN

//#define ENDSTOPPULLUP_KMIN

//#define ENDSTOPPULLUP_UMIN

//#define ENDSTOPPULLUP_VMIN

//#define ENDSTOPPULLUP_WMIN

//#define ENDSTOPPULLUP_XMAX

//#define ENDSTOPPULLUP_YMAX

//#define ENDSTOPPULLUP_ZMAX

//#define ENDSTOPPULLUP_IMAX

//#define ENDSTOPPULLUP_JMAX

//#define ENDSTOPPULLUP_KMAX

//#define ENDSTOPPULLUP_UMAX

//#define ENDSTOPPULLUP_VMAX

//#define ENDSTOPPULLUP_WMAX

//#define ENDSTOPPULLUP_ZMIN_PROBE

#endif

// Enable pulldown for all endstops to prevent a floating state

//#define ENDSTOPPULLDOWNS

#if DISABLED(ENDSTOPPULLDOWNS)

// Disable ENDSTOPPULLDOWNS to set pulldowns individually

//#define ENDSTOPPULLDOWN_XMIN

//#define ENDSTOPPULLDOWN_YMIN

//#define ENDSTOPPULLDOWN_ZMIN

//#define ENDSTOPPULLDOWN_IMIN

//#define ENDSTOPPULLDOWN_JMIN

//#define ENDSTOPPULLDOWN_KMIN

//#define ENDSTOPPULLDOWN_UMIN

//#define ENDSTOPPULLDOWN_VMIN

//#define ENDSTOPPULLDOWN_WMIN

//#define ENDSTOPPULLDOWN_XMAX

//#define ENDSTOPPULLDOWN_YMAX

//#define ENDSTOPPULLDOWN_ZMAX

//#define ENDSTOPPULLDOWN_IMAX

//#define ENDSTOPPULLDOWN_JMAX

//#define ENDSTOPPULLDOWN_KMAX

//#define ENDSTOPPULLDOWN_UMAX

//#define ENDSTOPPULLDOWN_VMAX

//#define ENDSTOPPULLDOWN_WMAX

//#define ENDSTOPPULLDOWN_ZMIN_PROBE

#endif

// Mechanical endstop with COM to ground and NC to Signal uses "false" here (most common setup).

#define X_MIN_ENDSTOP_INVERTING false // Set to true to invert the logic of the endstop.

#define Y_MIN_ENDSTOP_INVERTING false // Set to true to invert the logic of the endstop.

#define Z_MIN_ENDSTOP_INVERTING false // Set to true to invert the logic of the endstop.

#define I_MIN_ENDSTOP_INVERTING false // Set to true to invert the logic of the endstop.

#define J_MIN_ENDSTOP_INVERTING false // Set to true to invert the logic of the endstop.

#define K_MIN_ENDSTOP_INVERTING false // Set to true to invert the logic of the endstop.

#define U_MIN_ENDSTOP_INVERTING false // Set to true to invert the logic of the endstop.

#define V_MIN_ENDSTOP_INVERTING false // Set to true to invert the logic of the endstop.

#define W_MIN_ENDSTOP_INVERTING false // Set to true to invert the logic of the endstop.

#define X_MAX_ENDSTOP_INVERTING false // Set to true to invert the logic of the endstop.

#define Y_MAX_ENDSTOP_INVERTING false // Set to true to invert the logic of the endstop.

#define Z_MAX_ENDSTOP_INVERTING false // Set to true to invert the logic of the endstop.

#define I_MAX_ENDSTOP_INVERTING false // Set to true to invert the logic of the endstop.

#define J_MAX_ENDSTOP_INVERTING false // Set to true to invert the logic of the endstop.

#define K_MAX_ENDSTOP_INVERTING false // Set to true to invert the logic of the endstop.

#define U_MAX_ENDSTOP_INVERTING false // Set to true to invert the logic of the endstop.

#define V_MAX_ENDSTOP_INVERTING false // Set to true to invert the logic of the endstop.

#define W_MAX_ENDSTOP_INVERTING false // Set to true to invert the logic of the endstop.

#define Z_MIN_PROBE_ENDSTOP_INVERTING false // Set to true to invert the logic of the probe.

// Enable this feature if all enabled endstop pins are interrupt-capable.

// This will remove the need to poll the interrupt pins, saving many CPU cycles.

//#define ENDSTOP_INTERRUPTS_FEATURE

/

* Endstop Noise Threshold

*

* Enable if your probe or endstops falsely trigger due to noise.

*

* - Higher values may affect repeatability or accuracy of some bed probes.

* - To fix noise install a 100nF ceramic capacitor in parallel with the switch.

* - This feature is not required for common micro-switches mounted on PCBs

* based on the Makerbot design, which already have the 100nF capacitor.

*

* :[2,3,4,5,6,7]

*/

//#define ENDSTOP_NOISE_THRESHOLD 2

Артем, [16.09.2024 16:37]

// Check for stuck or disconnected endstops during homing moves.

//#define DETECT_BROKEN_ENDSTOP

//=============================================================================

//============================== Movement Settings ============================

//=============================================================================

// @section motion

/

* Default Settings

*

* These settings can be reset by M502

*

* Note that if EEPROM is enabled, saved values will override these.

*/

/

* With this option each E stepper can have its own factors for the

* following movement settings. If fewer factors are given than the

* total number of extruders, the last value applies to the rest.

*/

//#define DISTINCT_E_FACTORS

/

* Default Axis Steps Per Unit (linear=steps/mm, rotational=steps/°)

* Override with M92

* X, Y, Z [, I [, J [, K...]]], E0 [, E1[, E2...]]

*/

#define DEFAULT_AXIS_STEPS_PER_UNIT { 160, 160, 800, 820 }

/

* Default Max Feed Rate (linear=mm/s, rotational=°/s)

* Override with M203

* X, Y, Z [, I [, J [, K...]]], E0 [, E1[, E2...]]

*/

#define DEFAULT_MAX_FEEDRATE { 500, 500, 5, 50 }

//#define LIMITED_MAX_FR_EDITING // Limit edit via M203 or LCD to DEFAULT_MAX_FEEDRATE * 2

#if ENABLED(LIMITED_MAX_FR_EDITING)

#define MAX_FEEDRATE_EDIT_VALUES { 600, 600, 10, 50 } // ...or, set your own edit limits

#endif

/

* Default Max Acceleration (speed change with time) (linear=mm/(s^2), rotational=°/(s^2))

* (Maximum start speed for accelerated moves)

* Override with M201

* X, Y, Z [, I [, J [, K...]]], E0 [, E1[, E2...]]

*/

#define DEFAULT_MAX_ACCELERATION { 500, 500, 100, 1000 }

//#define LIMITED_MAX_ACCEL_EDITING // Limit edit via M201 or LCD to DEFAULT_MAX_ACCELERATION * 2

#if ENABLED(LIMITED_MAX_ACCEL_EDITING)

#define MAX_ACCEL_EDIT_VALUES { 6000, 6000, 200, 20000 } // ...or, set your own edit limits

#endif

/

* Default Acceleration (speed change with time) (linear=mm/(s^2), rotational=°/(s^2))

* Override with M204

*

* M204 P Acceleration

* M204 R Retract Acceleration

* M204 T Travel Acceleration

* M204 I Angular Acceleration

* M204 J Angular Travel Acceleration

*/

#define DEFAULT_ACCELERATION 500 // X, Y, Z ... and E acceleration for printing moves

#define DEFAULT_RETRACT_ACCELERATION 500 // E acceleration for retracts

#define DEFAULT_TRAVEL_ACCELERATION 1500 // X, Y, Z ... acceleration for travel (non printing) moves

#if ENABLED(AXIS4_ROTATES)

#define DEFAULT_ANGULAR_ACCELERATION 3000 // I, J, K acceleration for rotational-only printing moves

#define DEFAULT_ANGULAR_TRAVEL_ACCELERATION 3000 // I, J, K acceleration for rotational-only travel (non printing) moves

#endif

/

* Default Jerk limits (mm/s)

* Override with M205 X Y Z . . . E

*

* "Jerk" specifies the minimum speed change that requires acceleration.

* When changing speed and direction, if the difference is less than the

* value set here, it may happen instantaneously.

*/

#define CLASSIC_JERK

#if ENABLED(CLASSIC_JERK)

#define DEFAULT_XJERK 10.0

#define DEFAULT_YJERK 10.0

#define DEFAULT_ZJERK 0.3

//#define DEFAULT_IJERK 0.3

//#define DEFAULT_JJERK 0.3

//#define DEFAULT_KJERK 0.3

//#define DEFAULT_UJERK 0.3

//#define DEFAULT_VJERK 0.3

//#define DEFAULT_WJERK 0.3

//#define TRAVEL_EXTRA_XYJERK 0.0 // Additional jerk allowance for all travel moves

//#define LIMITED_JERK_EDITING // Limit edit via M205 or LCD to DEFAULT_aJERK * 2

#if ENABLED(LIMITED_JERK_EDITING)

#define MAX_JERK_EDIT_VALUES { 20, 20, 0.6, 10 } // ...or, set your own edit limits

#endif

#endif

#define DEFAULT_EJERK 5.0 // May be used by Linear Advance

Артем, [16.09.2024 16:37]

/

* Junction Deviation Factor

*

* See:

* https://reprap.org/forum/read.php?1,739819

* https://blog.kyneticcnc.com/2018/10/computing-junction-deviation-for-marlin.html

*/

#if DISABLED(CLASSIC_JERK)

#define JUNCTION_DEVIATION_MM 0.013 // (mm) Distance from real junction edge

#define JD_HANDLE_SMALL_SEGMENTS // Use curvature estimation instead of just the junction angle

// for small segments ( 135°).

#endif

/

// For Inverting Stepper Enable Pins (Active Low) use 0, Non Inverting (Active High) use 1

// :{ 0:'Low', 1:'High' }

#define X_ENABLE_ON 0

#define Y_ENABLE_ON 0

#define Z_ENABLE_ON 0

#define E_ENABLE_ON 0 // For all extruders

//#define I_ENABLE_ON 0

//#define J_ENABLE_ON 0

//#define K_ENABLE_ON 0

//#define U_ENABLE_ON 0

//#define V_ENABLE_ON 0

//#define W_ENABLE_ON 0

// Disable axis steppers immediately when they're not being stepped.

// WARNING: When motors turn off there is a chance of losing position accuracy!

#define DISABLE_X false

#define DISABLE_Y false

#define DISABLE_Z false

//#define DISABLE_I false

//#define DISABLE_J false

//#define DISABLE_K false

//#define DISABLE_U false

//#define DISABLE_V false

//#define DISABLE_W false

// Turn off the display blinking that warns about possible accuracy reduction

//#define DISABLE_REDUCED_ACCURACY_WARNING

// @section extruder

#define DISABLE_E false // Disable the extruder when not stepping

#define DISABLE_INACTIVE_EXTRUDER // Keep only the active extruder enabled

// @section motion

// Invert the stepper direction. Change (or reverse the motor connector) if an axis goes the wrong way.

#define INVERT_X_DIR true

#define INVERT_Y_DIR true

#define INVERT_Z_DIR false

//#define INVERT_I_DIR false

//#define INVERT_J_DIR false

//#define INVERT_K_DIR false

//#define INVERT_U_DIR false

//#define INVERT_V_DIR false

//#define INVERT_W_DIR false

// @section extruder

// For direct drive extruder v9 set to true, for geared extruder set to false.

#define INVERT_E0_DIR true

#define INVERT_E1_DIR false

#define INVERT_E2_DIR false

#define INVERT_E3_DIR false

#define INVERT_E4_DIR false

#define INVERT_E5_DIR false

#define INVERT_E6_DIR false

#define INVERT_E7_DIR false

// @section homing

//#define NO_MOTION_BEFORE_HOMING // Inhibit movement until all axes have been homed. Also enable HOME_AFTER_DEACTIVATE for extra safety.

//#define HOME_AFTER_DEACTIVATE // Require rehoming after steppers are deactivated. Also enable NO_MOTION_BEFORE_HOMING for extra safety.

Артем, [16.09.2024 16:37]

/

* Set Z_IDLE_HEIGHT if the Z-Axis moves on its own when steppers are disabled.

* - Use a low value (i.e., Z_MIN_POS) if the nozzle falls down to the bed.

* - Use a large value (i.e., Z_MAX_POS) if the bed falls down, away from the nozzle.

*/

//#define Z_IDLE_HEIGHT Z_HOME_POS

//#define Z_HOMING_HEIGHT 4 // (mm) Minimal Z height before homing (G28) for Z clearance above the bed, clamps, ...

// Be sure to have this much clearance over your Z_MAX_POS to prevent grinding.

//#define Z_AFTER_HOMING 10 // (mm) Height to move to after homing Z

// Direction of endstops when homing; 1=MAX, -1=MIN

// :[-1,1]

#define X_HOME_DIR -1

#define Y_HOME_DIR -1

#define Z_HOME_DIR -1

//#define I_HOME_DIR -1

//#define J_HOME_DIR -1

//#define K_HOME_DIR -1

//#define U_HOME_DIR -1

//#define V_HOME_DIR -1

//#define W_HOME_DIR -1

// @section geometry

// The size of the printable area

#define X_BED_SIZE 220

#define Y_BED_SIZE 220

// Travel limits (linear=mm, rotational=°) after homing, corresponding to endstop positions.

#define X_MIN_POS 0

#define Y_MIN_POS 0

#define Z_MIN_POS 0

#define X_MAX_POS X_BED_SIZE

#define Y_MAX_POS Y_BED_SIZE

#define Z_MAX_POS 235

//#define I_MIN_POS 0

//#define I_MAX_POS 50

//#define J_MIN_POS 0

//#define J_MAX_POS 50

//#define K_MIN_POS 0

//#define K_MAX_POS 50

//#define U_MIN_POS 0

//#define U_MAX_POS 50

//#define V_MIN_POS 0

//#define V_MAX_POS 50

//#define W_MIN_POS 0

//#define W_MAX_POS 50

/

* Software Endstops

*

* - Prevent moves outside the set machine bounds.

* - Individual axes can be disabled, if desired.

* - X and Y only apply to Cartesian robots.

* - Use 'M211' to set software endstops on/off or report current state

*/

// Min software endstops constrain movement within minimum coordinate bounds

#define MIN_SOFTWARE_ENDSTOPS

#if ENABLED(MIN_SOFTWARE_ENDSTOPS)

#define MIN_SOFTWARE_ENDSTOP_X

#define MIN_SOFTWARE_ENDSTOP_Y

#define MIN_SOFTWARE_ENDSTOP_Z

#define MIN_SOFTWARE_ENDSTOP_I

#define MIN_SOFTWARE_ENDSTOP_J

#define MIN_SOFTWARE_ENDSTOP_K

#define MIN_SOFTWARE_ENDSTOP_U

#define MIN_SOFTWARE_ENDSTOP_V

#define MIN_SOFTWARE_ENDSTOP_W

#endif

// Max software endstops constrain movement within maximum coordinate bounds

#define MAX_SOFTWARE_ENDSTOPS

#if ENABLED(MAX_SOFTWARE_ENDSTOPS)

#define MAX_SOFTWARE_ENDSTOP_X

#define MAX_SOFTWARE_ENDSTOP_Y

#define MAX_SOFTWARE_ENDSTOP_Z

#define MAX_SOFTWARE_ENDSTOP_I

#define MAX_SOFTWARE_ENDSTOP_J

#define MAX_SOFTWARE_ENDSTOP_K

#define MAX_SOFTWARE_ENDSTOP_U

#define MAX_SOFTWARE_ENDSTOP_V

#define MAX_SOFTWARE_ENDSTOP_W

#endif

* Configuration_adv.h

*

* Advanced settings.

* Only change these if you know exactly what you're doing.

* Some of these settings can damage your printer if improperly set!

*

* Basic settings can be found in Configuration.h

*/

#define CONFIGURATION_ADV_H_VERSION 02010200

// @section develop

/

* Configuration Export

*

* Export the configuration as part of the build. (See signature.py)

* Output files are saved with the build (e.g., .pio/build/mega2560).

*

* See `build_all_examples --ini` as an example of config.ini archiving.

*

* 1 = marlin_config.json - Dictionary containing the configuration.

* This file is also generated for CONFIGURATION_EMBEDDING.

* 2 = config.ini - File format for PlatformIO preprocessing.

* 3 = schema.json - The entire configuration schema. (13 = pattern groups)

* 4 = schema.yml - The entire configuration schema.

*/

//#define CONFIG_EXPORT 2 // :[1:'JSON', 2:'config.ini', 3:'schema.json', 4:'schema.yml']

//===========================================================================

//============================= Thermal Settings ============================

//===========================================================================

// @section temperature

/

* Thermocouple sensors are quite sensitive to noise. Any noise induced in

* the sensor wires, such as by stepper motor wires run in parallel to them,

* may result in the thermocouple sensor reporting spurious errors. This

* value is the number of errors which can occur in a row before the error

* is reported. This allows us to ignore intermittent error conditions while

* still detecting an actual failure, which should result in a continuous

* stream of errors from the sensor.

*

* Set this value to 0 to fail on the first error to occur.

*/

#define THERMOCOUPLE_MAX_ERRORS 15

//

// Custom Thermistor 1000 parameters

//

#if TEMP_SENSOR_0 == 1000

#define HOTEND0_PULLUP_RESISTOR_OHMS 4700 // Pullup resistor

#define HOTEND0_RESISTANCE_25C_OHMS 100000 // Resistance at 25C

#define HOTEND0_BETA 3950 // Beta value

#define HOTEND0_SH_C_COEFF 0 // Steinhart-Hart C coefficient

#endif

#if TEMP_SENSOR_1 == 1000

#define HOTEND1_PULLUP_RESISTOR_OHMS 4700 // Pullup resistor

#define HOTEND1_RESISTANCE_25C_OHMS 100000 // Resistance at 25C

#define HOTEND1_BETA 3950 // Beta value

#define HOTEND1_SH_C_COEFF 0 // Steinhart-Hart C coefficient

#endif

#if TEMP_SENSOR_2 == 1000

#define HOTEND2_PULLUP_RESISTOR_OHMS 4700 // Pullup resistor

#define HOTEND2_RESISTANCE_25C_OHMS 100000 // Resistance at 25C

#define HOTEND2_BETA 3950 // Beta value

#define HOTEND2_SH_C_COEFF 0 // Steinhart-Hart C coefficient

#endif

#if TEMP_SENSOR_3 == 1000

#define HOTEND3_PULLUP_RESISTOR_OHMS 4700 // Pullup resistor

#define HOTEND3_RESISTANCE_25C_OHMS 100000 // Resistance at 25C

#define HOTEND3_BETA 3950 // Beta value

#define HOTEND3_SH_C_COEFF 0 // Steinhart-Hart C coefficient

#endif

Артем, [16.09.2024 16:46]

#if TEMP_SENSOR_4 == 1000

#define HOTEND4_PULLUP_RESISTOR_OHMS 4700 // Pullup resistor

#define HOTEND4_RESISTANCE_25C_OHMS 100000 // Resistance at 25C

#define HOTEND4_BETA 3950 // Beta value

#define HOTEND4_SH_C_COEFF 0 // Steinhart-Hart C coefficient

#endif

#if TEMP_SENSOR_5 == 1000

#define HOTEND5_PULLUP_RESISTOR_OHMS 4700 // Pullup resistor

#define HOTEND5_RESISTANCE_25C_OHMS 100000 // Resistance at 25C

#define HOTEND5_BETA 3950 // Beta value

#define HOTEND5_SH_C_COEFF 0 // Steinhart-Hart C coefficient

#endif

#if TEMP_SENSOR_6 == 1000

#define HOTEND6_PULLUP_RESISTOR_OHMS 4700 // Pullup resistor

#define HOTEND6_RESISTANCE_25C_OHMS 100000 // Resistance at 25C

#define HOTEND6_BETA 3950 // Beta value

#define HOTEND6_SH_C_COEFF 0 // Steinhart-Hart C coefficient

#endif

#if TEMP_SENSOR_7 == 1000

#define HOTEND7_PULLUP_RESISTOR_OHMS 4700 // Pullup resistor

#define HOTEND7_RESISTANCE_25C_OHMS 100000 // Resistance at 25C

#define HOTEND7_BETA 3950 // Beta value

#define HOTEND7_SH_C_COEFF 0 // Steinhart-Hart C coefficient

#endif

#if TEMP_SENSOR_BED == 1000

#define BED_PULLUP_RESISTOR_OHMS 4700 // Pullup resistor

#define BED_RESISTANCE_25C_OHMS 100000 // Resistance at 25C

#define BED_BETA 3950 // Beta value

#define BED_SH_C_COEFF 0 // Steinhart-Hart C coefficient

#endif

#if TEMP_SENSOR_CHAMBER == 1000

#define CHAMBER_PULLUP_RESISTOR_OHMS 4700 // Pullup resistor

#define CHAMBER_RESISTANCE_25C_OHMS 100000 // Resistance at 25C

#define CHAMBER_BETA 3950 // Beta value

#define CHAMBER_SH_C_COEFF 0 // Steinhart-Hart C coefficient

#endif

#if TEMP_SENSOR_COOLER == 1000

#define COOLER_PULLUP_RESISTOR_OHMS 4700 // Pullup resistor

#define COOLER_RESISTANCE_25C_OHMS 100000 // Resistance at 25C

#define COOLER_BETA 3950 // Beta value

#define COOLER_SH_C_COEFF 0 // Steinhart-Hart C coefficient

#endif

#if TEMP_SENSOR_PROBE == 1000

#define PROBE_PULLUP_RESISTOR_OHMS 4700 // Pullup resistor

#define PROBE_RESISTANCE_25C_OHMS 100000 // Resistance at 25C

#define PROBE_BETA 3950 // Beta value

#define PROBE_SH_C_COEFF 0 // Steinhart-Hart C coefficient

#endif

#if TEMP_SENSOR_BOARD == 1000

#define BOARD_PULLUP_RESISTOR_OHMS 4700 // Pullup resistor

#define BOARD_RESISTANCE_25C_OHMS 100000 // Resistance at 25C

#define BOARD_BETA 3950 // Beta value

#define BOARD_SH_C_COEFF 0 // Steinhart-Hart C coefficient

#endif

#if TEMP_SENSOR_REDUNDANT == 1000

#define REDUNDANT_PULLUP_RESISTOR_OHMS 4700 // Pullup resistor

#define REDUNDANT_RESISTANCE_25C_OHMS 100000 // Resistance at 25C

#define REDUNDANT_BETA 3950 // Beta value

#define REDUNDANT_SH_C_COEFF 0 // Steinhart-Hart C coefficient

#endif

Артем, [16.09.2024 16:46]

/

* Thermocouple Options — for MAX6675 (-2), MAX31855 (-3), and MAX31865 (-5).

*/

//#define TEMP_SENSOR_FORCE_HW_SPI // Ignore SCK/MOSI/MISO pins; use CS and the default SPI bus.

//#define MAX31865_SENSOR_WIRES_0 2 // (2-4) Number of wires for the probe connected to a MAX31865 board.

//#define MAX31865_SENSOR_WIRES_1 2

//#define MAX31865_50HZ_FILTER // Use a 50Hz filter instead of the default 60Hz.

//#define MAX31865_USE_READ_ERROR_DETECTION // Treat value spikes (20°C delta in under 1s) as read errors.

//#define MAX31865_USE_AUTO_MODE // Read faster and more often than 1-shot; bias voltage always on; slight effect on RTD temperature.

//#define MAX31865_MIN_SAMPLING_TIME_MSEC 100 // (ms) 1-shot: minimum read interval. Reduces bias voltage effects by leaving sensor unpowered for longer intervals.

//#define MAX31865_IGNORE_INITIAL_FAULTY_READS 10 // Ignore some read faults (keeping the temperature reading) to work around a possible issue (#23439).

//#define MAX31865_WIRE_OHMS_0 0.95f // For 2-wire, set the wire resistances for more accurate readings.

//#define MAX31865_WIRE_OHMS_1 0.0f

/

* Hephestos 2 24V heated bed upgrade kit.

* https://store.bq.com/en/heated-bed-kit-hephestos2

*/

//#define HEPHESTOS2_HEATED_BED_KIT

#if ENABLED(HEPHESTOS2_HEATED_BED_KIT)

#undef TEMP_SENSOR_BED

#define TEMP_SENSOR_BED 70

#define HEATER_BED_INVERTING true

#endif

//

// Heated Bed Bang-Bang options

//

#if DISABLED(PIDTEMPBED)

#define BED_CHECK_INTERVAL 5000 // (ms) Interval between checks in bang-bang control

#if ENABLED(BED_LIMIT_SWITCHING)

#define BED_HYSTERESIS 2 // (°C) Only set the relevant heater state when ABS(T-target) > BED_HYSTERESIS

#endif

#endif

//

// Heated Chamber options

//

#if DISABLED(PIDTEMPCHAMBER)

#define CHAMBER_CHECK_INTERVAL 5000 // (ms) Interval between checks in bang-bang control

#if ENABLED(CHAMBER_LIMIT_SWITCHING)

#define CHAMBER_HYSTERESIS 2 // (°C) Only set the relevant heater state when ABS(T-target) > CHAMBER_HYSTERESIS

#endif

#endif

#if TEMP_SENSOR_CHAMBER

//#define HEATER_CHAMBER_PIN P2_04 // Required heater on/off pin (example: SKR 1.4 Turbo HE1 plug)

//#define HEATER_CHAMBER_INVERTING false

//#define FAN1_PIN -1 // Remove the fan signal on pin P2_04 (example: SKR 1.4 Turbo HE1 plug)

//#define CHAMBER_FAN // Enable a fan on the chamber

#if ENABLED(CHAMBER_FAN)

//#define CHAMBER_FAN_INDEX 2 // Index of a fan to repurpose as the chamber fan. (Default: first unused fan)

#define CHAMBER_FAN_MODE 2 // Fan control mode: 0=Static; 1=Linear increase when temp is higher than target; 2=V-shaped curve; 3=similar to 1 but fan is always on.

#if CHAMBER_FAN_MODE == 0

#define CHAMBER_FAN_BASE 255 // Chamber fan PWM (0-255)

#elif CHAMBER_FAN_MODE == 1

#define CHAMBER_FAN_BASE 128 // Base chamber fan PWM (0-255); turns on when chamber temperature is above the target

#define CHAMBER_FAN_FACTOR 25 // PWM increase per °C above target

#elif CHAMBER_FAN_MODE == 2

#define CHAMBER_FAN_BASE 128 // Minimum chamber fan PWM (0-255)

#define CHAMBER_FAN_FACTOR 25 // PWM increase per °C difference from target

#elif CHAMBER_FAN_MODE == 3

#define CHAMBER_FAN_BASE 128 // Base chamber fan PWM (0-255)

#define CHAMBER_FAN_FACTOR 25 // PWM increase per °C above target

#endif

#endif

//#define CHAMBER_VENT // Enable a servo-controlled vent on the chamber

#if ENABLED(CHAMBER_VENT)

#define CHAMBER_VENT_SERVO_NR 1 // Index of the vent servo

#define HIGH_EXCESS_HEAT_LIMIT 5 // How much above target temp to consider there is excess heat in the chamber

#define LOW_EXCESS_HEAT_LIMIT 3

#define MIN_COOLING_SLOPE_TIME_CHAMBER_VENT 20

#define MIN_COOLING_SLOPE_DEG_CHAMBER_VENT 1.5

#endif

#endif

Артем, [16.09.2024 16:46]

//

// Laser Cooler options

//

#if TEMP_SENSOR_COOLER

#define COOLER_MINTEMP 8 // (°C)

#define COOLER_MAXTEMP 26 // (°C)

#define COOLER_DEFAULT_TEMP 16 // (°C)

#define TEMP_COOLER_HYSTERESIS 1 // (°C) Temperature proximity considered "close enough" to the target

#define COOLER_PIN 8 // Laser cooler on/off pin used to control power to the cooling element (e.g., TEC, External chiller via relay)

#define COOLER_INVERTING false

#define TEMP_COOLER_PIN 15 // Laser/Cooler temperature sensor pin. ADC is required.

#define COOLER_FAN // Enable a fan on the cooler, Fan# 0,1,2,3 etc.

#define COOLER_FAN_INDEX 0 // FAN number 0, 1, 2 etc. e.g.

#if ENABLED(COOLER_FAN)

#define COOLER_FAN_BASE 100 // Base Cooler fan PWM (0-255); turns on when Cooler temperature is above the target

#define COOLER_FAN_FACTOR 25 // PWM increase per °C above target

#endif

#endif

//

// Motherboard Sensor options

//

#if TEMP_SENSOR_BOARD

#define THERMAL_PROTECTION_BOARD // Halt the printer if the board sensor leaves the temp range below.

#define BOARD_MINTEMP 8 // (°C)

#define BOARD_MAXTEMP 70 // (°C)

#ifndef TEMP_BOARD_PIN

//#define TEMP_BOARD_PIN -1 // Board temp sensor pin, if not set in pins file.

#endif

#endif

/

* Thermal Protection provides additional protection to your printer from damage

* and fire. Marlin always includes safe min and max temperature ranges which

* protect against a broken or disconnected thermistor wire.

*

* The issue: If a thermistor falls out, it will report the much lower

* temperature of the air in the room, and the the firmware will keep

* the heater on.

*

* The solution: Once the temperature reaches the target, start observing.

* If the temperature stays too far below the target (hysteresis) for too

* long (period), the firmware will halt the machine as a safety precaution.

*

* If you get false positives for "Thermal Runaway", increase

* THERMAL_PROTECTION_HYSTERESIS and/or THERMAL_PROTECTION_PERIOD

*/

#if ENABLED(THERMAL_PROTECTION_HOTENDS)

#define THERMAL_PROTECTION_PERIOD 40 // Seconds

#define THERMAL_PROTECTION_HYSTERESIS 4 // Degrees Celsius

//#define ADAPTIVE_FAN_SLOWING // Slow part cooling fan if temperature drops

#if BOTH(ADAPTIVE_FAN_SLOWING, PIDTEMP)

//#define NO_FAN_SLOWING_IN_PID_TUNING // Don't slow fan speed during M303

#endif

/

* Whenever an M104, M109, or M303 increases the target temperature, the

* firmware will wait for the WATCH_TEMP_PERIOD to expire. If the temperature

* hasn't increased by WATCH_TEMP_INCREASE degrees, the machine is halted and

* requires a hard reset. This test restarts with any M104/M109/M303, but only

* if the current temperature is far enough below the target for a reliable

* test.

*

* If you get false positives for "Heating failed", increase WATCH_TEMP_PERIOD

* and/or decrease WATCH_TEMP_INCREASE. WATCH_TEMP_INCREASE should not be set

* below 2.

*/

#define WATCH_TEMP_PERIOD 40 // Seconds

#define WATCH_TEMP_INCREASE 2 // Degrees Celsius

#endif

/

* Thermal Protection parameters for the bed are just as above for hotends.

*/

#if ENABLED(THERMAL_PROTECTION_BED)

#define THERMAL_PROTECTION_BED_PERIOD 20 // Seconds

#define THERMAL_PROTECTION_BED_HYSTERESIS 2 // Degrees Celsius

/

* As described above, except for the bed (M140/M190/M303).

*/

#define WATCH_BED_TEMP_PERIOD 60 // Seconds

#define WATCH_BED_TEMP_INCREASE 2 // Degrees Celsius

#endif

Артем, [16.09.2024 16:46]

/

* Thermal Protection parameters for the heated chamber.

*/

#if ENABLED(THERMAL_PROTECTION_CHAMBER)

#define THERMAL_PROTECTION_CHAMBER_PERIOD 20 // Seconds

#define THERMAL_PROTECTION_CHAMBER_HYSTERESIS 2 // Degrees Celsius

/

* Heated chamber watch settings (M141/M191).

*/

#define WATCH_CHAMBER_TEMP_PERIOD 60 // Seconds

#define WATCH_CHAMBER_TEMP_INCREASE 2 // Degrees Celsius

#endif

/

* Thermal Protection parameters for the laser cooler.

*/

#if ENABLED(THERMAL_PROTECTION_COOLER)

#define THERMAL_PROTECTION_COOLER_PERIOD 10 // Seconds

#define THERMAL_PROTECTION_COOLER_HYSTERESIS 3 // Degrees Celsius

/

* Laser cooling watch settings (M143/M193).

*/

#define WATCH_COOLER_TEMP_PERIOD 60 // Seconds

#define WATCH_COOLER_TEMP_INCREASE 3 // Degrees Celsius

#endif

#if ANY(THERMAL_PROTECTION_HOTENDS, THERMAL_PROTECTION_BED, THERMAL_PROTECTION_CHAMBER, THERMAL_PROTECTION_COOLER)

/

* Thermal Protection Variance Monitor - EXPERIMENTAL.

* Kill the machine on a stuck temperature sensor. Disable if you get false positives.

*/

//#define THERMAL_PROTECTION_VARIANCE_MONITOR // Detect a sensor malfunction preventing temperature updates

#endif

#if ENABLED(PIDTEMP)

// Add an experimental additional term to the heater power, proportional to the extrusion speed.

// A well-chosen Kc value should add just enough power to melt the increased material volume.

//#define PID_EXTRUSION_SCALING

#if ENABLED(PID_EXTRUSION_SCALING)

#define DEFAULT_Kc (100) // heating power = Kc * e_speed

#define LPQ_MAX_LEN 50

#endif

/

* Add an experimental additional term to the heater power, proportional to the fan speed.

* A well-chosen Kf value should add just enough power to compensate for power-loss from the cooling fan.

* You can either just add a constant compensation with the DEFAULT_Kf value

* or follow the instruction below to get speed-dependent compensation.

*

* Constant compensation (use only with fanspeeds of 0% and 100%)

* ---------------------------------------------------------------------

* A good starting point for the Kf-value comes from the calculation:

* kf = (power_fan * eff_fan) / power_heater * 255

* where eff_fan is between 0.0 and 1.0, based on fan-efficiency and airflow to the nozzle / heater.

*

* Example:

* Heater: 40W, Fan: 0.1A * 24V = 2.4W, eff_fan = 0.8

* Kf = (2.4W * 0.8) / 40W * 255 = 12.24

*

* Fan-speed dependent compensation

* --------------------------------

* 1. To find a good Kf value, set the hotend temperature, wait for it to settle, and enable the fan (100%).

* Make sure PID_FAN_SCALING_LIN_FACTOR is 0 and PID_FAN_SCALING_ALTERNATIVE_DEFINITION is not enabled.

* If you see the temperature drop repeat the test, increasing the Kf value slowly, until the temperature

* drop goes away. If the temperature overshoots after enabling the fan, the Kf value is too big.

* 2. Note the Kf-value for fan-speed at 100%

* 3. Determine a good value for PID_FAN_SCALING_MIN_SPEED, which is around the speed, where the fan starts moving.

* 4. Repeat step 1. and 2. for this fan speed.

* 5. Enable PID_FAN_SCALING_ALTERNATIVE_DEFINITION and enter the two identified Kf-values in

* PID_FAN_SCALING_AT_FULL_SPEED and PID_FAN_SCALING_AT_MIN_SPEED. Enter the minimum speed in PID_FAN_SCALING_MIN_SPEED

*/

//#define PID_FAN_SCALING

#if ENABLED(PID_FAN_SCALING)

//#define PID_FAN_SCALING_ALTERNATIVE_DEFINITION

#if ENABLED(PID_FAN_SCALING_ALTERNATIVE_DEFINITION)

// The alternative definition is used for an easier configuration.

// Just figure out Kf at fullspeed (255) and PID_FAN_SCALING_MIN_SPEED.

// DEFAULT_Kf and PID_FAN_SCALING_LIN_FACTOR are calculated accordingly.

Артем, [16.09.2024 16:46]

#define PID_FAN_SCALING_AT_FULL_SPEED 13.0 //=PID_FAN_SCALING_LIN_FACTOR*255+DEFAULT_Kf

#define PID_FAN_SCALING_AT_MIN_SPEED 6.0 //=PID_FAN_SCALING_LIN_FACTOR*PID_FAN_SCALING_MIN_SPEED+DEFAULT_Kf

#define PID_FAN_SCALING_MIN_SPEED 10.0 // Minimum fan speed at which to enable PID_FAN_SCALING

#define DEFAULT_Kf (255.0*PID_FAN_SCALING_AT_MIN_SPEED-PID_FAN_SCALING_AT_FULL_SPEED*PID_FAN_SCALING_MIN_SPEED)/(255.0-PID_FAN_SCALING_MIN_SPEED)

#define PID_FAN_SCALING_LIN_FACTOR (PID_FAN_SCALING_AT_FULL_SPEED-DEFAULT_Kf)/255.0

#else

#define PID_FAN_SCALING_LIN_FACTOR (0) // Power loss due to cooling = Kf * (fan_speed)

#define DEFAULT_Kf 10 // A constant value added to the PID-tuner

#define PID_FAN_SCALING_MIN_SPEED 10 // Minimum fan speed at which to enable PID_FAN_SCALING

#endif

#endif

#endif

/

* Automatic Temperature Mode

*

* Dynamically adjust the hotend target temperature based on planned E moves.

*

* (Contrast with PID_EXTRUSION_SCALING, which tracks E movement and adjusts PID

* behavior using an additional kC value.)

*

* Autotemp is calculated by (mintemp + factor * mm_per_sec), capped to maxtemp.

*

* Enable Autotemp Mode with M104/M109 F S B.

* Disable by sending M104/M109 with no F parameter (or F0 with AUTOTEMP_PROPORTIONAL).

*/

#define AUTOTEMP

#if ENABLED(AUTOTEMP)

#define AUTOTEMP_OLDWEIGHT 0.98 // Factor used to weight previous readings (0.0 0 in the constants below

*/

// The number of consecutive low temperature errors that can occur

// before a min_temp_error is triggered. (Shouldn't be more than 10.)

//#define MAX_CONSECUTIVE_LOW_TEMPERATURE_ERROR_ALLOWED 0

/

* The number of milliseconds a hotend will preheat before starting to check

* the temperature. This value should NOT be set to the time it takes the

* hot end to reach the target temperature, but the time it takes to reach

* the minimum temperature your thermistor can read. The lower the better/safer.

* This shouldn't need to be more than 30 seconds (30000)

*/

//#define MILLISECONDS_PREHEAT_TIME 0

// @section extruder

/

* Extruder runout prevention.

* If the machine is idle and the temperature over MINTEMP

* then extrude some filament every couple of SECONDS.

*/

//#define EXTRUDER_RUNOUT_PREVENT

#if ENABLED(EXTRUDER_RUNOUT_PREVENT)

#define EXTRUDER_RUNOUT_MINTEMP 190

#define EXTRUDER_RUNOUT_SECONDS 30

#define EXTRUDER_RUNOUT_SPEED 1500 // (mm/min)

#define EXTRUDER_RUNOUT_EXTRUDE 5 // (mm)

#endif

Артем, [16.09.2024 16:46]

/

* Hotend Idle Timeout

* Prevent filament in the nozzle from charring and causing a critical jam.

*/

//#define HOTEND_IDLE_TIMEOUT

#if ENABLED(HOTEND_IDLE_TIMEOUT)

#define HOTEND_IDLE_TIMEOUT_SEC (5*60) // (seconds) Time without extruder movement to trigger protection

#define HOTEND_IDLE_MIN_TRIGGER 180 // (°C) Minimum temperature to enable hotend protection

#define HOTEND_IDLE_NOZZLE_TARGET 0 // (°C) Safe temperature for the nozzle after timeout

#define HOTEND_IDLE_BED_TARGET 0 // (°C) Safe temperature for the bed after timeout

#endif

// @section temperature

// Calibration for AD595 / AD8495 sensor to adjust temperature measurements.

// The final temperature is calculated as (measuredTemp * GAIN) + OFFSET.

#define TEMP_SENSOR_AD595_OFFSET 0.0

#define TEMP_SENSOR_AD595_GAIN 1.0

#define TEMP_SENSOR_AD8495_OFFSET 0.0

#define TEMP_SENSOR_AD8495_GAIN 1.0

/

* Controller Fan

* To cool down the stepper drivers and MOSFETs.

*

* The fan turns on automatically whenever any driver is enabled and turns

* off (or reduces to idle speed) shortly after drivers are turned off.

*/

//#define USE_CONTROLLER_FAN

#if ENABLED(USE_CONTROLLER_FAN)

//#define CONTROLLER_FAN_PIN -1 // Set a custom pin for the controller fan

//#define CONTROLLER_FAN_USE_Z_ONLY // With this option only the Z axis is considered

//#define CONTROLLER_FAN_IGNORE_Z // Ignore Z stepper. Useful when stepper timeout is disabled.

#define CONTROLLERFAN_SPEED_MIN 0 // (0-255) Minimum speed. (If set below this value the fan is turned off.)

#define CONTROLLERFAN_SPEED_ACTIVE 255 // (0-255) Active speed, used when any motor is enabled

#define CONTROLLERFAN_SPEED_IDLE 0 // (0-255) Idle speed, used when motors are disabled

#define CONTROLLERFAN_IDLE_TIME 60 // (seconds) Extra time to keep the fan running after disabling motors

// Use TEMP_SENSOR_BOARD as a trigger for enabling the controller fan

//#define CONTROLLER_FAN_MIN_BOARD_TEMP 40 // (°C) Turn on the fan if the board reaches this temperature

//#define CONTROLLER_FAN_EDITABLE // Enable M710 configurable settings

#if ENABLED(CONTROLLER_FAN_EDITABLE)

#define CONTROLLER_FAN_MENU // Enable the Controller Fan submenu

#endif

#endif

// When first starting the main fan, run it at full speed for the

// given number of milliseconds. This gets the fan spinning reliably

// before setting a PWM value. (Does not work with software PWM for fan on Sanguinololu)

//#define FAN_KICKSTART_TIME 100

// Some coolers may require a non-zero "off" state.

//#define FAN_OFF_PWM 1

Артем, [16.09.2024 16:46]

/

* PWM Fan Scaling

*

* Define the min/max speeds for PWM fans (as set with M106).

*

* With these options the M106 0-255 value range is scaled to a subset

* to ensure that the fan has enough power to spin, or to run lower

* current fans with higher current. (e.g., 5V/12V fans with 12V/24V)

* Value 0 always turns off the fan.

*

* Define one or both of these to override the default 0-255 range.

*/

//#define FAN_MIN_PWM 50

//#define FAN_MAX_PWM 128

/

* Fan Fast PWM

*

* Combinations of PWM Modes, prescale values and TOP resolutions are used internally

* to produce a frequency as close as possible to the desired frequency.

*

* FAST_PWM_FAN_FREQUENCY

* Set this to your desired frequency.

* For AVR, if left undefined this defaults to F = F_CPU/(2*255*1)

* i.e., F = 31.4kHz on 16MHz microcontrollers or F = 39.2kHz on 20MHz microcontrollers.

* For non AVR, if left undefined this defaults to F = 1Khz.

* This F value is only to protect the hardware from an absence of configuration

* and not to complete it when users are not aware that the frequency must be specifically set to support the target board.

*

* NOTE: Setting very low frequencies (:

*

* 0 : (FULL_CONTROL) The slicer has full control over both X-carriages and can achieve optimal travel

* results as long as it supports dual X-carriages. (M605 S0)

*

* 1 : (AUTO_PARK) The firmware automatically parks and unparks the X-carriages on tool-change so

* that additional slicer support is not required. (M605 S1)

*

Артем, [16.09.2024 16:46]

* 2 : (DUPLICATION) The firmware moves the second X-carriage and extruder in synchronization with

* the first X-carriage and extruder, to print 2 copies of the same object at the same time.

* Set the constant X-offset and temperature differential with M605 S2 X[offs] R[deg] and

* follow with M605 S2 to initiate duplicated movement.

*

* 3 : (MIRRORED) Formbot/Vivedino-inspired mirrored mode in which the second extruder duplicates

* the movement of the first except the second extruder is reversed in the X axis.

* Set the initial X offset and temperature differential with M605 S2 X[offs] R[deg] and

* follow with M605 S3 to initiate mirrored movement.

*/

//#define DUAL_X_CARRIAGE

#if ENABLED(DUAL_X_CARRIAGE)

#define X1_MIN_POS X_MIN_POS // Set to X_MIN_POS

#define X1_MAX_POS X_BED_SIZE // A max coordinate so the X1 carriage can't hit the parked X2 carriage

#define X2_MIN_POS 80 // A min coordinate so the X2 carriage can't hit the parked X1 carriage

#define X2_MAX_POS 353 // The max position of the X2 carriage, typically also the home position

#define X2_HOME_DIR 1 // Set to 1. The X2 carriage always homes to the max endstop position

#define X2_HOME_POS X2_MAX_POS // Default X2 home position. Set to X2_MAX_POS.

// NOTE: For Dual X Carriage use M218 T1 Xn to override the X2_HOME_POS.

// This allows recalibration of endstops distance without a rebuild.

// Remember to set the second extruder's X-offset to 0 in your slicer.

// This is the default power-up mode which can be changed later using M605 S.

#define DEFAULT_DUAL_X_CARRIAGE_MODE DXC_AUTO_PARK_MODE

// Default x offset in duplication mode (typically set to half print bed width)

#define DEFAULT_DUPLICATION_X_OFFSET 100

// Default action to execute following M605 mode change commands. Typically G28X to apply new mode.

//#define EVENT_GCODE_IDEX_AFTER_MODECHANGE "G28X"

#endif

Артем, [16.09.2024 16:46]

/

* Multi-Stepper / Multi-Endstop

*

* When X2_DRIVER_TYPE is defined, this indicates that the X and X2 motors work in tandem.

* The following explanations for X also apply to Y and Z multi-stepper setups.

* Endstop offsets may be changed by 'M666 X Y Z' and stored to EEPROM.

*

* - Enable INVERT_X2_VS_X_DIR if the X2 motor requires an opposite DIR signal from X.

*

* - Enable X_DUAL_ENDSTOPS if the second motor has its own endstop, with adjustable offset.

*

* - Extra endstops are included in the output of 'M119'.

*

* - Set X_DUAL_ENDSTOP_ADJUSTMENT to the known error in the X2 endstop.

* Applied to the X2 motor on 'G28' / 'G28 X'.

* Get the offset by homing X and measuring the error.

* Also set with 'M666 X' and stored to EEPROM with 'M500'.

*

* - Use X2_USE_ENDSTOP to set the endstop plug by name. (_XMIN_, _XMAX_, _YMIN_, _YMAX_, _ZMIN_, _ZMAX_)

*/

#if HAS_X2_STEPPER && DISABLED(DUAL_X_CARRIAGE)

//#define INVERT_X2_VS_X_DIR // X2 direction signal is the opposite of X

//#define X_DUAL_ENDSTOPS // X2 has its own endstop

#if ENABLED(X_DUAL_ENDSTOPS)

#define X2_USE_ENDSTOP _XMAX_ // X2 endstop board plug. Don't forget to enable USE_*_PLUG.

#define X2_ENDSTOP_ADJUSTMENT 0 // X2 offset relative to X endstop

#endif

#endif

#if HAS_DUAL_Y_STEPPERS

//#define INVERT_Y2_VS_Y_DIR // Y2 direction signal is the opposite of Y

//#define Y_DUAL_ENDSTOPS // Y2 has its own endstop

#if ENABLED(Y_DUAL_ENDSTOPS)

#define Y2_USE_ENDSTOP _YMAX_ // Y2 endstop board plug. Don't forget to enable USE_*_PLUG.

#define Y2_ENDSTOP_ADJUSTMENT 0 // Y2 offset relative to Y endstop

#endif

#endif

//

// Multi-Z steppers

//

#ifdef Z2_DRIVER_TYPE

//#define INVERT_Z2_VS_Z_DIR // Z2 direction signal is the opposite of Z

//#define Z_MULTI_ENDSTOPS // Other Z axes have their own endstops

#if ENABLED(Z_MULTI_ENDSTOPS)

#define Z2_USE_ENDSTOP _XMAX_ // Z2 endstop board plug. Don't forget to enable USE_*_PLUG.

#define Z2_ENDSTOP_ADJUSTMENT 0 // Z2 offset relative to Y endstop

#endif

#ifdef Z3_DRIVER_TYPE

//#define INVERT_Z3_VS_Z_DIR // Z3 direction signal is the opposite of Z

#if ENABLED(Z_MULTI_ENDSTOPS)

#define Z3_USE_ENDSTOP _YMAX_ // Z3 endstop board plug. Don't forget to enable USE_*_PLUG.

#define Z3_ENDSTOP_ADJUSTMENT 0 // Z3 offset relative to Y endstop

#endif

#endif

#ifdef Z4_DRIVER_TYPE

//#define INVERT_Z4_VS_Z_DIR // Z4 direction signal is the opposite of Z

#if ENABLED(Z_MULTI_ENDSTOPS)

#define Z4_USE_ENDSTOP _ZMAX_ // Z4 endstop board plug. Don't forget to enable USE_*_PLUG.

#define Z4_ENDSTOP_ADJUSTMENT 0 // Z4 offset relative to Y endstop

#endif

#endif

#endif

// Drive the E axis with two synchronized steppers

//#define E_DUAL_STEPPER_DRIVERS

#if ENABLED(E_DUAL_STEPPER_DRIVERS)

//#define INVERT_E1_VS_E0_DIR // E direction signals are opposites

#endif

// Activate a solenoid on the active extruder with M380. Disable all with M381.

// Define SOL0_PIN, SOL1_PIN, etc., for each extruder that has a solenoid.

//#define EXT_SOLENOID

// @section homing

/

* Homing Procedure

* Homing (G28) does an indefinite move towards the endstops to establish

* the position of the toolhead relative to the workspace.

*/

//#define SENSORLESS_BACKOFF_MM { 2, 2, 0 } // (linear=mm, rotational=°) Backoff from endstops before sensorless homing

#define HOMING_BUMP_MM { 5, 5, 2 } // (linear=mm, rotational=°) Backoff from endstops after first bump

#define HOMING_BUMP_DIVISOR { 2, 2, 4 } // Re-Bump Speed Divisor (Divides the Homing Feedrate)

//#define HOMING_BACKOFF_POST_MM { 2, 2, 2 } // (linear=mm, rotational=°) Backoff from endstops after homing

//#define XY_COUNTERPART_BACKOFF_MM 0 // (mm) Backoff X after homing Y, and vice-versa

Артем, [16.09.2024 16:46]

//#define QUICK_HOME // If G28 contains XY do a diagonal move first

//#define HOME_Y_BEFORE_X // If G28 contains XY home Y before X

//#define HOME_Z_FIRST // Home Z first. Requires a Z-MIN endstop (not a probe).

//#define CODEPENDENT_XY_HOMING // If X/Y can't home without homing Y/X first

// @section bltouch

#if ENABLED(BLTOUCH)

/

* Either: Use the defaults (recommended) or: For special purposes, use the following DEFINES

* Do not activate settings that the probe might not understand. Clones might misunderstand

* advanced commands.

*

* Note: If the probe is not deploying, do a "Reset" and "Self-Test" and then check the

* wiring of the BROWN, RED and ORANGE wires.

*

* Note: If the trigger signal of your probe is not being recognized, it has been very often

* because the BLACK and WHITE wires needed to be swapped. They are not "interchangeable"

* like they would be with a real switch. So please check the wiring first.

*

* Settings for all BLTouch and clone probes:

*/

// Safety: The probe needs time to recognize the command.

// Minimum command delay (ms). Enable and increase if needed.

//#define BLTOUCH_DELAY 500

/

* Settings for BLTOUCH Classic 1.2, 1.3 or BLTouch Smart 1.0, 2.0, 2.2, 3.0, 3.1, and most clones:

*/

// Feature: Switch into SW mode after a deploy. It makes the output pulse longer. Can be useful

// in special cases, like noisy or filtered input configurations.

//#define BLTOUCH_FORCE_SW_MODE

/

* Settings for BLTouch Smart 3.0 and 3.1

* Summary:

* - Voltage modes: 5V and OD (open drain - "logic voltage free") output modes

* - High-Speed mode

* - Disable LCD voltage options

*/

/

* Danger: Don't activate 5V mode unless attached to a 5V-tolerant controller!

* V3.0 or 3.1: Set default mode to 5V mode at Marlin startup.

* If disabled, OD mode is the hard-coded default on 3.0

* On startup, Marlin will compare its eeprom to this value. If the selected mode

* differs, a mode set eeprom write will be completed at initialization.

* Use the option below to force an eeprom write to a V3.1 probe regardless.

*/

//#define BLTOUCH_SET_5V_MODE

/

* Safety: Activate if connecting a probe with an unknown voltage mode.

* V3.0: Set a probe into mode selected above at Marlin startup. Required for 5V mode on 3.0

* V3.1: Force a probe with unknown mode into selected mode at Marlin startup ( = Probe EEPROM write )

* To preserve the life of the probe, use this once then turn it off and re-flash.

*/

//#define BLTOUCH_FORCE_MODE_SET

/

* Enable "HIGH SPEED" option for probing.

* Danger: Disable if your probe sometimes fails. Only suitable for stable well-adjusted systems.

* This feature was designed for Deltabots with very fast Z moves; however, higher speed Cartesians

* might be able to use it. If the machine can't raise Z fast enough the BLTouch may go into ALARM.

*

* Set the default state here, change with 'M401 S' or UI, use M500 to save, M502 to reset.

*/

//#define BLTOUCH_HS_MODE true

// Safety: Enable voltage mode settings in the LCD menu.

//#define BLTOUCH_LCD_VOLTAGE_MENU

#endif // BLTOUCH

// @section extras

/

* Z Steppers Auto-Alignment

* Add the G34 command to align multiple Z steppers using a bed probe.

*/

//#define Z_STEPPER_AUTO_ALIGN

#if ENABLED(Z_STEPPER_AUTO_ALIGN)

/

* Define probe X and Y positions for Z1, Z2 [, Z3 [, Z4]]

* These positions are machine-relative and do not shift with the M206 home offset!

* If not defined, probe limits will be used.

* Override with 'M422 S X Y'.

*/

//#define Z_STEPPER_ALIGN_XY { { 10, 190 }, { 100, 10 }, { 190, 190 } }

Артем, [16.09.2024 16:46]

/

* Orientation for the automatically-calculated probe positions.

* Override Z stepper align points with 'M422 S X Y'

*

* 2 Steppers: (0) (1)

* | | 2 |

* | 1 2 | |

* | | 1 |

*

* 3 Steppers: (0) (1) (2) (3)

* | 3 | 1 | 2 1 | 2 |

* | | 3 | | 3 |

* | 1 2 | 2 | 3 | 1 |

*

* 4 Steppers: (0) (1) (2) (3)

* | 4 3 | 1 4 | 2 1 | 3 2 |

* | | | | |

* | 1 2 | 2 3 | 3 4 | 4 1 |

*/

#ifndef Z_STEPPER_ALIGN_XY

//#define Z_STEPPERS_ORIENTATION 0

#endif

/

* Z Stepper positions for more rapid convergence in bed alignment.

* Requires 3 or 4 Z steppers.

*

* Define Stepper XY positions for Z1, Z2, Z3... corresponding to the screw

* positions in the bed carriage, with one position per Z stepper in stepper

* driver order.

*/

//#define Z_STEPPER_ALIGN_STEPPER_XY { { 210.7, 102.5 }, { 152.6, 220.0 }, { 94.5, 102.5 } }

#ifndef Z_STEPPER_ALIGN_STEPPER_XY

// Amplification factor. Used to scale the correction step up or down in case

// the stepper (spindle) position is farther out than the test point.

#define Z_STEPPER_ALIGN_AMP 1.0 // Use a value > 1.0 NOTE: This may cause instability!

#endif

// On a 300mm bed a 5% grade would give a misalignment of ~1.5cm

#define G34_MAX_GRADE 5 // (%) Maximum incline that G34 will handle

#define Z_STEPPER_ALIGN_ITERATIONS 5 // Number of iterations to apply during alignment

#define Z_STEPPER_ALIGN_ACC 0.02 // Stop iterating early if the accuracy is better than this

#define RESTORE_LEVELING_AFTER_G34 // Restore leveling after G34 is done?

// After G34, re-home Z (G28 Z) or just calculate it from the last probe heights?

// Re-homing might be more precise in reproducing the actual 'G28 Z' homing height, especially on an uneven bed.

#define HOME_AFTER_G34

#endif

//

// Add the G35 command to read bed corners to help adjust screws. Requires a bed probe.

//

//#define ASSISTED_TRAMMING

#if ENABLED(ASSISTED_TRAMMING)

// Define positions for probe points.

#define TRAMMING_POINT_XY { { 20, 20 }, { 180, 20 }, { 180, 180 }, { 20, 180 } }

// Define position names for probe points.

#define TRAMMING_POINT_NAME_1 "Front-Left"

#define TRAMMING_POINT_NAME_2 "Front-Right"

#define TRAMMING_POINT_NAME_3 "Back-Right"

#define TRAMMING_POINT_NAME_4 "Back-Left"

#define RESTORE_LEVELING_AFTER_G35 // Enable to restore leveling setup after operation

//#define REPORT_TRAMMING_MM // Report Z deviation (mm) for each point relative to the first

//#define ASSISTED_TRAMMING_WIZARD // Add a Tramming Wizard to the LCD menu

//#define ASSISTED_TRAMMING_WAIT_POSITION { X_CENTER, Y_CENTER, 30 } // Move the nozzle out of the way for adjustment

Артем, [16.09.2024 16:46]

/

* Screw thread:

* M3: 30 = Clockwise, 31 = Counter-Clockwise

* M4: 40 = Clockwise, 41 = Counter-Clockwise

* M5: 50 = Clockwise, 51 = Counter-Clockwise

*/

#define TRAMMING_SCREW_THREAD 30

#endif

// @section motion

#define AXIS_RELATIVE_MODES { false, false, false, false }

// Add a Duplicate option for well-separated conjoined nozzles

//#define MULTI_NOZZLE_DUPLICATION

// By default pololu step drivers require an active high signal. However, some high power drivers require an active low signal as step.

#define INVERT_X_STEP_PIN false

#define INVERT_Y_STEP_PIN false

#define INVERT_Z_STEP_PIN false

#define INVERT_I_STEP_PIN false

#define INVERT_J_STEP_PIN false

#define INVERT_K_STEP_PIN false

#define INVERT_U_STEP_PIN false

#define INVERT_V_STEP_PIN false

#define INVERT_W_STEP_PIN false

#define INVERT_E_STEP_PIN false

/

* Idle Stepper Shutdown

* Set DISABLE_INACTIVE_? 'true' to shut down axis steppers after an idle period.

* The Deactive Time can be overridden with M18 and M84. Set to 0 for No Timeout.

*/

#define DEFAULT_STEPPER_DEACTIVE_TIME 120

#define DISABLE_INACTIVE_X true

#define DISABLE_INACTIVE_Y true

#define DISABLE_INACTIVE_Z true // Set 'false' if the nozzle could fall onto your printed part!

#define DISABLE_INACTIVE_I true

#define DISABLE_INACTIVE_J true

#define DISABLE_INACTIVE_K true

#define DISABLE_INACTIVE_U true

#define DISABLE_INACTIVE_V true

#define DISABLE_INACTIVE_W true

#define DISABLE_INACTIVE_E true

// Default Minimum Feedrates for printing and travel moves

#define DEFAULT_MINIMUMFEEDRATE 0.0 // (mm/s. °/s for rotational-only moves) Minimum feedrate. Set with M205 S.

#define DEFAULT_MINTRAVELFEEDRATE 0.0 // (mm/s. °/s for rotational-only moves) Minimum travel feedrate. Set with M205 T.

// Minimum time that a segment needs to take as the buffer gets emptied

#define DEFAULT_MINSEGMENTTIME 20000 // (µs) Set with M205 B.

// Slow down the machine if the lookahead buffer is (by default) half full.

// Increase the slowdown divisor for larger buffer sizes.

#define SLOWDOWN

#if ENABLED(SLOWDOWN)

#define SLOWDOWN_DIVISOR 2

#endif

Артем, [16.09.2024 16:46]

/

* XY Frequency limit

* Reduce resonance by limiting the frequency of small zigzag infill moves.

* See https://hydraraptor.blogspot.com/2010/12/frequency-limit.html

* Use M201 F G to change limits at runtime.

*/

//#define XY_FREQUENCY_LIMIT 10 // (Hz) Maximum frequency of small zigzag infill moves. Set with M201 F.

#ifdef XY_FREQUENCY_LIMIT

#define XY_FREQUENCY_MIN_PERCENT 5 // (percent) Minimum FR percentage to apply. Set with M201 G.

#endif

// Minimum planner junction speed. Sets the default minimum speed the planner plans for at the end

// of the buffer and all stops. This should not be much greater than zero and should only be changed

// if unwanted behavior is observed on a user's machine when running at very slow speeds.

#define MINIMUM_PLANNER_SPEED 0.05 // (mm/s)

//

// Backlash Compensation

// Adds extra movement to axes on direction-changes to account for backlash.

//

//#define BACKLASH_COMPENSATION

#if ENABLED(BACKLASH_COMPENSATION)

// Define values for backlash distance and correction.

// If BACKLASH_GCODE is enabled these values are the defaults.

#define BACKLASH_DISTANCE_MM { 0, 0, 0 } // (linear=mm, rotational=°) One value for each linear axis

#define BACKLASH_CORRECTION 0.0 // 0.0 = no correction; 1.0 = full correction

// Add steps for motor direction changes on CORE kinematics

//#define CORE_BACKLASH

// Set BACKLASH_SMOOTHING_MM to spread backlash correction over multiple segments

// to reduce print artifacts. (Enabling this is costly in memory and computation!)

//#define BACKLASH_SMOOTHING_MM 3 // (mm)

// Add runtime configuration and tuning of backlash values (M425)

//#define BACKLASH_GCODE

#if ENABLED(BACKLASH_GCODE)

// Measure the Z backlash when probing (G29) and set with "M425 Z"

#define MEASURE_BACKLASH_WHEN_PROBING

#if ENABLED(MEASURE_BACKLASH_WHEN_PROBING)

// When measuring, the probe will move up to BACKLASH_MEASUREMENT_LIMIT

// mm away from point of contact in BACKLASH_MEASUREMENT_RESOLUTION

// increments while checking for the contact to be broken.

#define BACKLASH_MEASUREMENT_LIMIT 0.5 // (mm)

#define BACKLASH_MEASUREMENT_RESOLUTION 0.005 // (mm)

#define BACKLASH_MEASUREMENT_FEEDRATE Z_PROBE_FEEDRATE_SLOW // (mm/min)

#endif

#endif

#endif

/

* Automatic backlash, position and hotend offset calibration

*

* Enable G425 to run automatic calibration using an electrically-

* conductive cube, bolt, or washer mounted on the bed.

*

* G425 uses the probe to touch the top and sides of the calibration object

* on the bed and measures and/or correct positional offsets, axis backlash

* and hotend offsets.

*

* Note: HOTEND_OFFSET and CALIBRATION_OBJECT_CENTER must be set to within

* ±5mm of true values for G425 to succeed.

*/

//#define CALIBRATION_GCODE

#if ENABLED(CALIBRATION_GCODE)

//#define CALIBRATION_SCRIPT_PRE "M117 Starting Auto-Calibration\nT0\nG28\nG12\nM117 Calibrating..."

//#define CALIBRATION_SCRIPT_POST "M500\nM117 Calibration data saved"

#define CALIBRATION_MEASUREMENT_RESOLUTION 0.01 // mm

#define CALIBRATION_FEEDRATE_SLOW 60 // mm/min

#define CALIBRATION_FEEDRATE_FAST 1200 // mm/min

#define CALIBRATION_FEEDRATE_TRAVEL 3000 // mm/min

// The following parameters refer to the conical section of the nozzle tip.

#define CALIBRATION_NOZZLE_TIP_HEIGHT 1.0 // mm

#define CALIBRATION_NOZZLE_OUTER_DIAMETER 2.0 // mm

// Uncomment to enable reporting (required for "G425 V", but consumes PROGMEM).

//#define CALIBRATION_REPORTING

// The true location and dimension the cube/bolt/washer on the bed.

#define CALIBRATION_OBJECT_CENTER { 264.0, -22.0, -2.0 } // mm

#define CALIBRATION_OBJECT_DIMENSIONS { 10.0, 10.0, 10.0 } // mm

Артем, [16.09.2024 16:46]

// Comment out any sides which are unreachable by the probe. For best

// auto-calibration results, all sides must be reachable.

#define CALIBRATION_MEASURE_RIGHT

#define CALIBRATION_MEASURE_FRONT

#define CALIBRATION_MEASURE_LEFT

#define CALIBRATION_MEASURE_BACK

//#define CALIBRATION_MEASURE_IMIN

//#define CALIBRATION_MEASURE_IMAX

//#define CALIBRATION_MEASURE_JMIN

//#define CALIBRATION_MEASURE_JMAX

//#define CALIBRATION_MEASURE_KMIN

//#define CALIBRATION_MEASURE_KMAX

//#define CALIBRATION_MEASURE_UMIN

//#define CALIBRATION_MEASURE_UMAX

//#define CALIBRATION_MEASURE_VMIN

//#define CALIBRATION_MEASURE_VMAX

//#define CALIBRATION_MEASURE_WMIN

//#define CALIBRATION_MEASURE_WMAX

// Probing at the exact top center only works if the center is flat. If

// probing on a screwhead or hollow washer, probe near the edges.

//#define CALIBRATION_MEASURE_AT_TOP_EDGES

// Define the pin to read during calibration

#ifndef CALIBRATION_PIN

//#define CALIBRATION_PIN -1 // Define here to override the default pin

#define CALIBRATION_PIN_INVERTING false // Set to true to invert the custom pin

//#define CALIBRATION_PIN_PULLDOWN

#define CALIBRATION_PIN_PULLUP

#endif

#endif

/

* Adaptive Step Smoothing increases the resolution of multi-axis moves, particularly at step frequencies

* below 1kHz (for AVR) or 10kHz (for ARM), where aliasing between axes in multi-axis moves causes audible

* vibration and surface artifacts. The algorithm adapts to provide the best possible step smoothing at the

* lowest stepping frequencies.

*/

//#define ADAPTIVE_STEP_SMOOTHING

/

* Custom Microstepping

* Override as-needed for your setup. Up to 3 MS pins are supported.

*/

//#define MICROSTEP1 LOW,LOW,LOW

//#define MICROSTEP2 HIGH,LOW,LOW

//#define MICROSTEP4 LOW,HIGH,LOW

//#define MICROSTEP8 HIGH,HIGH,LOW

//#define MICROSTEP16 LOW,LOW,HIGH

//#define MICROSTEP32 HIGH,LOW,HIGH

// Microstep settings (Requires a board with pins named X_MS1, X_MS2, etc.)

#define MICROSTEP_MODES { 16, 16, 16, 16, 16, 16 } // [1,2,4,8,16]

/

* @section stepper motor current

*

* Some boards have a means of setting the stepper motor current via firmware.

*

* The power on motor currents are set by:

* PWM_MOTOR_CURRENT - used by MINIRAMBO & ULTIMAIN_2

* known compatible chips: A4982

* DIGIPOT_MOTOR_CURRENT - used by BQ_ZUM_MEGA_3D, RAMBO & SCOOVO_X9H

* known compatible chips: AD5206

* DAC_MOTOR_CURRENT_DEFAULT - used by PRINTRBOARD_REVF & RIGIDBOARD_V2

* known compatible chips: MCP4728

* DIGIPOT_I2C_MOTOR_CURRENTS - used by 5DPRINT, AZTEEG_X3_PRO, AZTEEG_X5_MINI_WIFI, MIGHTYBOARD_REVE

* known compatible chips: MCP4451, MCP4018

*

* Motor currents can also be set by M907 - M910 and by the LCD.

* M907 - applies to all.

* M908 - BQ_ZUM_MEGA_3D, RAMBO, PRINTRBOARD_REVF, RIGIDBOARD_V2 & SCOOVO_X9H

* M909, M910 & LCD - only PRINTRBOARD_REVF & RIGIDBOARD_V2

*/

//#define PWM_MOTOR_CURRENT { 1300, 1300, 1250 } // Values in milliamps

//#define DIGIPOT_MOTOR_CURRENT { 135,135,135,135,135 } // Values 0-255 (RAMBO 135 = ~0.75A, 185 = ~1A)

//#define DAC_MOTOR_CURRENT_DEFAULT { 70, 80, 90, 80 } // Default drive percent - X, Y, Z, E axis

/

* I2C-based DIGIPOTs (e.g., Azteeg X3 Pro)

*/

//#define DIGIPOT_MCP4018 // Requires https://github.com/felias-fogg/SlowSoftI2CMaster

//#define DIGIPOT_MCP4451

#if EITHER(DIGIPOT_MCP4018, DIGIPOT_MCP4451)

#define DIGIPOT_I2C_NUM_CHANNELS 8 // 5DPRINT:4 AZTEEG_X3_PRO:8 MKS_SBASE:5 MIGHTYBOARD_REVE:5

// Actual motor currents in Amps. The number of entries must match DIGIPOT_I2C_NUM_CHANNELS.

// These correspond to the physical drivers, so be mindful if the order is changed.

#define DIGIPOT_I2C_MOTOR_CURRENTS { 1.0, 1.0, 1.0, 1.0, 1.0, 1.0, 1.0, 1.0 } // AZTEEG_X3_PRO

//#define DIGIPOT_USE_RAW_VALUES // Use DIGIPOT_MOTOR_CURRENT raw wiper values (instead of A4988 motor currents)

Артем, [16.09.2024 16:46]

/

* Common slave addresses:

*

* A (A shifted) B (B shifted) IC

* Smoothie 0x2C (0x58) 0x2D (0x5A) MCP4451

* AZTEEG_X3_PRO 0x2C (0x58) 0x2E (0x5C) MCP4451

* AZTEEG_X5_MINI 0x2C (0x58) 0x2E (0x5C) MCP4451

* AZTEEG_X5_MINI_WIFI 0x58 0x5C MCP4451

* MIGHTYBOARD_REVE 0x2F (0x5E) MCP4018

*/

//#define DIGIPOT_I2C_ADDRESS_A 0x2C // Unshifted slave address for first DIGIPOT

//#define DIGIPOT_I2C_ADDRESS_B 0x2D // Unshifted slave address for second DIGIPOT

#endif

//===========================================================================

//=============================Additional Features===========================

//===========================================================================

// @section lcd

#if HAS_MANUAL_MOVE_MENU

#define MANUAL_FEEDRATE { 50*60, 50*60, 4*60, 2*60 } // (mm/min) Feedrates for manual moves along X, Y, Z, E from panel

#define FINE_MANUAL_MOVE 0.025 // (mm) Smallest manual move (' and list long filenames with 'M20 L'

//#define LONG_FILENAME_WRITE_SUPPORT // Create / delete files with long filenames via M28, M30, and Binary Transfer Protocol

//#define M20_TIMESTAMP_SUPPORT // Include timestamps by adding the 'T' flag to M20 commands

//#define SCROLL_LONG_FILENAMES // Scroll long filenames in the SD card menu

//#define SD_ABORT_NO_COOLDOWN // Leave the heaters on after Stop Print (not recommended!)

/

* Abort SD printing when any endstop is triggered.

* This feature is enabled with 'M540 S1' or from the LCD menu.

Комментарии и вопросы

сначала лайкнул а потом подума...

Так-то оно конечно, не настоль...

Да, PETg разный (в т.ч. углена...

Плата разветвивтель на несколь...

Принтер Creality K2 с хранилищ...

Например на нижнем или верхнем...

Ну например послал на печать и...