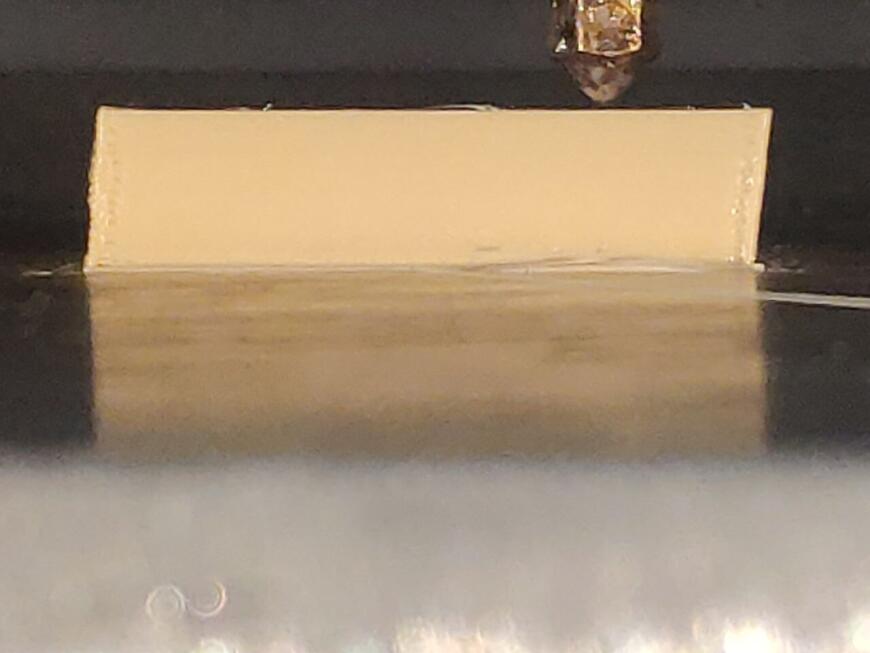

Печать с постоянным смещением в одну сторону.

Всем привет. Собрал принтер. Кинематика h-bot. Прошивка клиппер.

Даже не помню чтоб с таким раньше сталкивался на других принтерах.

В общем печатает он со стабильным смещением в обе стороны.

Что это может быть?

[include mainsail.cfg]

[printer]

kinematics: corexy

max_velocity: 10000

max_accel: 1000

max_z_velocity: 3

max_z_accel: 80

[stepper_x]

step_pin: PF13

dir_pin: !PF12

enable_pin: !PF14

microsteps: 16

rotation_distance: 36

endstop_pin: !PG14

position_endstop: 0

position_max: 305

homing_speed: 20

[stepper_y]

step_pin: PG0

dir_pin: !PG1

enable_pin: !PF15

microsteps: 16

rotation_distance: 36

endstop_pin: !PG15 # endstop have'!' is NO

position_min: 0

position_endstop:305

position_max: 305

homing_speed: 20

[stepper_z]

step_pin: PF11

dir_pin: !PG3

enable_pin: !PG5

microsteps: 256

rotation_distance: 1.2

endstop_pin: PG12 # endstop have'!' is NO

position_endstop: 438

#step_pulse_duration: 0.000000800

position_max: 438

homing_speed: 3

second_homing_speed:2

[extruder]

step_pin: PE6

dir_pin: !PA14

enable_pin: !PE0

microsteps: 16

rotation_distance: 25

nozzle_diameter: 0.400

filament_diameter: 1.750

heater_pin: PA2

sensor_type: ATC Semitec 104NT-4-R025H42G

sensor_pin: PF5

#control: pid

#pid_Kp: 22

#pid_Ki: 1.08

#pid_Kd: 114

min_temp: 0

max_temp: 260

max_extrude_cross_section: 0.9 # если ругается, увеличить

#min_extrude_temp: 170

########################################

# TMC UART configuration

########################################

[tmc2208 stepper_x]

uart_pin: PC4

run_current: 0.8

hold_current: 0.5

stealthchop_threshold: 999999

[tmc2208 stepper_y]

uart_pin: PD11

run_current: 0.8

hold_current: 0.5

stealthchop_threshold: 999999

[tmc2208 stepper_z]

uart_pin: PC6

run_current: 1.3

hold_current: 0.5

interpolate: True

stealthchop_threshold: 999999

[tmc2208 extruder]

uart_pin: PD3

run_current: 1.0

hold_current: 0.5

sense_resistor: 0.110

stealthchop_threshold: 999999

###################################################################

[heater_bed]

heater_pin: PB11

sensor_type: EPCOS 100K B57560G104F

sensor_pin: PF6

max_power: 1.0

control = pid

pid_kp = 72.484

pid_ki = 1.837

pid_kd = 714.877

min_temp: 0

max_temp: 200

#fan for printed model FAN0

[fan]

pin: PD12

##fan for hotend FAN1

[heater_fan fan1]

pin: PE5

shutdown_speed: 1

##########################################################

##########################################################

##########################################################

#fan for control board FAN2

#[heater_fan my_control_fan]

[heater_fan fan2]

pin: PA8

shutdown_speed: 1

[mcu]

serial: /dev/serial/by-id/usb-Klipper_stm32f429xx_400039001551303439373431-if00

baud: 250000

restart_method: command

#####################################################################

# LED Control

#####################################################################

#[output_pin caselight ](Use PA9)

## Chamber Lighting - In 5V-RGB Position

#pin: PA9

#pwm: true

#shutdown_value: 0

#value:100

#cycle_time: 0.01

########################################

# EXP1 / EXP2 (display) pins

########################################

[board_pins]

aliases:

# EXP1 header

EXP1_1=PB2, EXP1_3=PE11, EXP1_5=PD9, EXP1_7=PE15, EXP1_9=,

EXP1_2=PE10, EXP1_4=PD10, EXP1_6=PD8, EXP1_8=PE7, EXP1_10=,

# EXP2 header

EXP2_1=PA6, EXP2_3=PE9, EXP2_5=PE8, EXP2_7=PB11, EXP2_9=,

EXP2_2=PA5, EXP2_4=PA4, EXP2_6=PA7, EXP2_8=, EXP2_10=

# Pins EXP2_1, EXP2_6, EXP2_2 are also MISO, MOSI, SCK of bus "ssp1"

# See the MKS Lcd Config path file for definitions of common LCD displays.

##############################################################################

[gcode_macro PRINT_START]

# Use PRINT_START for the slicer starting script - please customise for your slicer of choice

gcode:

G32 ; home all axes

G1 Z20 F3000 ; move nozzle away from bed

[gcode_macro PRINT_END]

# Use PRINT_END for the slicer ending script - please customise for your slicer of choice

gcode:

M400 ; wait for buffer to clear

G92 E0 ; zero the extruder

G1 E-10.0 F3600 ; retract filament

G91 ; relative positioning

G0 Z1.00 X20.0 Y20.0 F20000 ; move nozzle to remove stringing

TURN_OFF_HEATERS

M107 ; turn off fan

G1 Z2 F3000 ; move nozzle up 2mm

G90 ; absolute positioning

G0 X125 Y250 F3600 ; park nozzle at rear

BED_MESH_CLEAR

#---------------------------------------------------- Mainsail-----------------------------------------------------#

[virtual_sdcard]

path: /home/fedonkin/i_data/gcodes

on_error_gcode:

CANCEL_PRINT

[pause_resume]

[display_status]

[gcode_macro CANCEL_PRINT]

description: Cancel the actual running print

rename_existing: CANCEL_PRINT_BASE

variable_park: True

gcode:

## Move head and retract only if not already in the pause state and park set to true

{% if printer.pause_resume.is_paused|lower == 'false' and park|lower == 'true'%}

_TOOLHEAD_PARK_PAUSE_CANCEL

{% endif %}

TURN_OFF_HEATERS

M106 S0

CANCEL_PRINT_BASE

[gcode_macro PAUSE]

description: Pause the actual running print

rename_existing: PAUSE_BASE

gcode:

PAUSE_BASE

_TOOLHEAD_PARK_PAUSE_CANCEL

[gcode_macro RESUME]

description: Resume the actual running print

rename_existing: RESUME_BASE

gcode:

##### read extrude from _TOOLHEAD_PARK_PAUSE_CANCEL macro #####

{% set extrude = printer['gcode_macro _TOOLHEAD_PARK_PAUSE_CANCEL'].extrude %}

#### get VELOCITY parameter if specified ####

{% if 'VELOCITY' in params|upper %}

{% set get_params = ('VELOCITY=' + params.VELOCITY) %}

{%else %}

{% set get_params = "" %}

{% endif %}

##### end of definitions #####

{% if printer.extruder.can_extrude|lower == 'true' %}

M83

G1 E{extrude} F2100

{% if printer.gcode_move.absolute_extrude |lower == 'true' %} M82 {% endif %}

{% else %}

{action_respond_info("Extruder not hot enough")}

{% endif %}

RESUME_BASE {get_params}

#*#

#*# DO NOT EDIT THIS BLOCK OR BELOW. The contents are auto-generated.

#*#

#*# [extruder]

#*# control = pid

#*# pid_kp = 44.272

#*# pid_ki = 4.043

#*# pid_kd = 121.194

#*#

#*# [heater_bed]

#*# control = pid

#*# pid_kp = 72.484

#*# pid_ki = 1.837

#*# pid_kd = 714.877

Популярные вопросы

Печать картины

Высушится ли нейлон при 50-52 градусах?

Могу только в термокамеру принтера его ки...

Чем 3D принтер отличается от 3D плоттера?

На занятиях по моделированию один школьник спросил - Чем 3D принтер отличается от 3D плоттера и что лучше для нови...

Комментарии и вопросы

Насмотрелся тут хвалебных стат...

Концевой выключатель и его кре...

Я поставил медную пластину в р...

Не могу найти свой принтер в P...

Принтеру Anycubic Kobra 2 Neo...

посоветуйте камеру что бы цепа...

Добрый день, поставил печатать...