Klippper и все радости его конфигурации

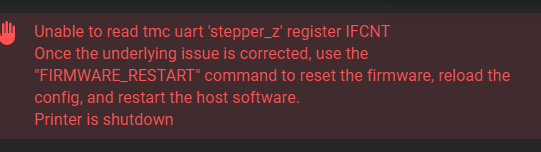

такая проблема плата мкс 3.1 tmc2209 что не так

такая проблема плата мкс 3.1 tmc2209 что не так

[stepper_x]

step_pin: PE3

dir_pin: !PE2

enable_pin: !PE4

microsteps: 16

rotation_distance: 40

endstop_pin: !PA15

position_endstop: 0

position_max: 300

homing_speed: 50

[stepper_y]

step_pin: PE0

dir_pin: !PB9

enable_pin: !PE1

microsteps: 16

rotation_distance: 40

endstop_pin: !PD2

position_endstop: 0

position_max: 300

homing_speed: 50

[stepper_z]

step_pin: PB5

dir_pin: !PB4

enable_pin: !PB8

microsteps: 16

rotation_distance: 40

endstop_pin: probe:z_virtual_endstop

position_min: -5

#position_endstop:0

position_max: 330

[bltouch]

sensor_pin: PC8

control_pin: PA8

pin_move_time: 0.5

pin_up_reports_not_triggered: true

pin_up_touch_mode_reports_triggered: false

x_offset: 0

y_offset: -30

z_offset: 1

speed: 2

[probe]

#probe_with_touch_mode: False

#samples_tolerance_retries: 0

#samples_tolerance: 0.100

#samples_result: average

#lift_speed: 10

#amples: 2

#[bed_mesh]

#samples: 1

#horizontal_move_z: 10

#min_point: 60,40

#max_point: 235,200

#probe_count: 4,4

#mesh_pps: 2, 2

#fade_start: 1.0

[safe_z_home]

home_xy_position: 150, 150 # Change coordinates to the center of your print bed

speed: 50

z_hop: 10 # Move up 10mm

z_hop_speed: 5

[force_move]

enable_force_move: true

[tmc2209 stepper_x]

uart_pin: PD5

#tx_pin: PD5

#diag_pin:

run_current: 0.880

#hold_current: 0.500

stealthchop_threshold: 99999

uart_address:0

[tmc2209 stepper_y]

uart_pin: PD7

#tx_pin: PD7

#diag_pin:

run_current: 0.880

#hold_current: 0.500

stealthchop_threshold: 99999

uart_address:1

[tmc2209 stepper_z]

uart_pin: PD4

#tx_pin: PD4

#diag_pin:

run_current: 0.880

#hold_current: 0.450

stealthchop_threshold: 99999

uart_address:2

[tmc2209 extruder]

uart_pin: PD9

#tx_pin: PD9

#diag_pin:

run_current: 0.600

#hold_current: 0.500

stealthchop_threshold: 99999

uart_address:3

[extruder]

step_pin: PD6

dir_pin: !PD3

enable_pin: !PB3

microsteps:16

rotation_distance: 33.500

nozzle_diameter: 0.400

filament_diameter: 1.750

heater_pin: PE5

sensor_type: ATC Semitec 104GT-2

sensor_pin: PC1

#control: pid

#pid_Kp: 14.669

#pid_Ki: 0.572

#pid_Kd: 94.068

min_temp: 0

max_temp: 260

#[extruder1]

#step_pin: PD15

#dir_pin: !PA1

#enable_pin: !PA3

#heater_pin: PB0

#sensor_pin: PA2

#...

[heater_bed]

heater_pin: PA0

sensor_type: EPCOS 100K B57560G104F

sensor_pin: PC0

#control: pid

#pid_Kp: 325.10

#pid_Ki: 63.35

#pid_Kd: 417.10

min_temp: 0

max_temp: 130

[fan]

pin: PC14 # fan1

#pin: PB1 # fan2

[mcu]

serial: /dev/serial/by-id/usb-Klipper_stm32f407xx_29001C000150305148383820-if00

[printer]

kinematics: corexy

max_velocity: 200

max_accel: 4500

max_z_velocity: 25

max_z_accel: 100

########################################

# EXP1 / EXP2 (display) pins

########################################

[board_pins]

aliases:

# EXP1 header

EXP1_1=PC5, EXP1_3=PD13, EXP1_5=PE14, EXP1_7=PD11, EXP1_9=,

EXP1_2=PE13, EXP1_4=PC6, EXP1_6=PE15, EXP1_8=PD10, EXP1_10=,

# EXP2 header

EXP2_1=PA6, EXP2_3=PE8, EXP2_5=PE11, EXP2_7=PE12, EXP2_9=,

EXP2_2=PA5, EXP2_4=PE10, EXP2_6=PA7, EXP2_8=, EXP2_10=

# Pins EXP2_1, EXP2_6, EXP2_2 are also MISO, MOSI, SCK of bus "ssp1"

# See the sample-lcd.cfg file for definitions of common LCD displays.

[display_status]

[pause_resume]

[virtual_sdcard]

path: ~/printer_data/gcodes

[gcode_macro RESUME]

description: Resume the actual running print

rename_existing: RESUME_BASE

gcode:

##### read E from pause macro #####

{% set E = printer["gcode_macro PAUSE"].extrude|float %}

#### get VELOCITY parameter if specified ####

{% if 'VELOCITY' in params|upper %}

{% set get_params = ('VELOCITY=' + params.VELOCITY) %}

{%else %}

{% set get_params = "" %}

{% endif %}

##### end of definitions #####

{% if printer.extruder.can_extrude|lower == 'true' %}

G91

G1 E{E} F2100

{% else %}

{action_respond_info("Extruder not hot enough")}

{% endif %}

RESUME_BASE {get_params}

[gcode_macro PAUSE]

description: Pause the actual running print

rename_existing: PAUSE_BASE

# change this if you need more or less extrusion

variable_extrude: 1.0

gcode:

##### read E from pause macro #####

{% set E = printer["gcode_macro PAUSE"].extrude|float %}

##### set park positon for x and y #####

# default is your max posion from your printer.cfg

{% set x_park = printer.toolhead.axis_maximum.x|float - 5.0 %}

{% set y_park = printer.toolhead.axis_maximum.y|float - 5.0 %}

##### calculate save lift position #####

{% set max_z = printer.toolhead.axis_maximum.z|float %}

{% set act_z = printer.toolhead.position.z|float %}

{% if act_z

#*# DO NOT EDIT THIS BLOCK OR BELOW. The contents are auto-generated.

#*#

#*# [extruder]

#*# control = pid

#*# pid_kp = 24.297

#*# pid_ki = 1.361

#*# pid_kd = 108.426

#*#

#*# [heater_bed]

#*# control = pid

#*# pid_kp = 74.458

#*# pid_ki = 0.914

#*# pid_kd = 1516.156

Комментарии и вопросы

Благодарю за отзыв.Так, собств...

Шикарное превью с икрой на хле...

Там же даже написано на изобра...

Пользователи сайта, всем приве...

Всем бобра. К о подскажет где...

Добрый день! На днях купил при...

С определенного момента пласти...